Filquip has been providing hopper and silo discharging systems for over 20 years for all types of powders and granular materials. The use of Live Bin Bottom Mass Flow Screw Conveyors are perfect for for discharging particularly difficult materials from hoppers or silos.

Live Silo/Bin Bottoms MU

Live Silo/Bin Bottoms MU

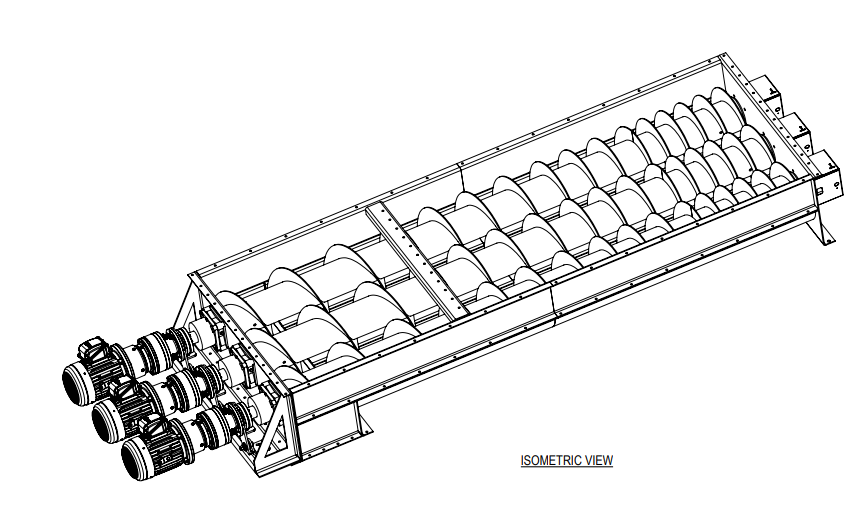

MU Live Bin Bottoms are the ideal solution for discharging particularly difficult materials from polygonal hoppers or silos.

MU Live Bin Bottom Feeders are used for extracting biological or industrial sludge, paper scrap, wood chippings, sawdust, flour, bran, chemical pellets and many other products. They are equipped with a modular trough which encloses up to 6 shafted helical flight or paddle screws, with fully protected end bearing assemblies complete with manually adjustable packing gland and shaft seal, a rectangular outlet spout covering the entire width of the bin bottom, bolted end plates, splined shaft couplings for medium duty, and flanged shaft couplings for the heavy-duty version.

MU Live Bin Bottoms are equipped with one gear motor per screw shaft or, depending on the application, with a drive unit driving more screws.

- Up to 6 shafted helicoid flight or paddle screws for product movement.

- Screw diameters from 150 to 600mm and trough length from 1,500 to 6,000mm.

- Available in Carbon steel or Stainless steel

Open MU Live Bin Bottom Screw Feeder Brochure