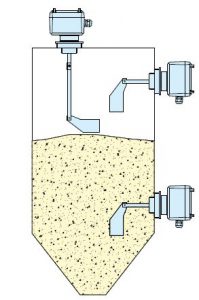

Functionality of the Silo Overfill Protection System

The Filquip silo overfill protection safety system consists of all the required items for ensuring the silo being filled cannot be over pressurized or overfilled and eliminates dust emissions:

- Control panel – Available with key control to ensure the correct product is filled into the correct silo and with the ability to manage multiple silos.

- Pinch valves – Controls and isolates different silo fill lines.

- High level indicator – Provides feedback when the silo has reached a pre-set high level.

- Differential pressure switch or electronic pressure meter – Measure in silo pressure.

- Pressure Relief Valve (PRV) – Safety valve to release excess pressure in silo.

- Dust collector – Venting of excess air without any dust emissions.

- Ducting kit to vent to ground – Ducting from the PRV and Dust Collector to ground.

- Wear bends/elbows – Abrasion resistant pipe bends and elbows for the silo filling lines.

- Pneumatic fittings – Air regulators, fittings and airline required for pneumatic plumbing.

Note: Available in 24VDC, 24VAC, 110V and 240V options.

Open Filquip Silo Overfill Protection Brochure

Silo Overfill Protection System

Silo Overfill Protection System

Filquip can supply a tailored silo overfill protection system to suit any system, to prevent dangerous over pressurisation and over filling, while eliminating dust emissions.

- Avoid damage to silo and accessories.

- Reduce the risk of air pollution.

- Eliminate the risk of filling the incorrect silo.

- Start and stop the filter cleaner automatically.

- Systems can be tailored to suit applications including the need for Pressure monitoring, Over pressure or vacuum release valves, Fill control, Dust control and Operator destination selection panel.

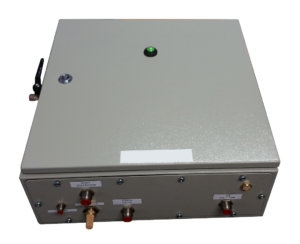

Electrical Control Panel

Electrical Control Panel

The Electrical Control Panel operates the overfill protection system and contains the logic to control to control the filling based on inputs from the level indicators and pressure switches.

- The Control Panel is fitted with a different key for each silo, when each silos key is turned on the; high level indicator begins rotating, dust collector initiates its cleaning cycle, and the fill pipe valve opens allowing silo filling to commence.

- Once the high-level indicator senses product at a pre-set high level, a light will begin flashing and an alarm will sound for a pre-set period of approximately 30 seconds before the fill line pinch valve is closed to prevent over-filling.

- The 30 second delay allows truck drivers to shut down their filling procedure.

- The alarm will sound until the key switch has been turned off or the level in the silo drops below the high level indicator.

- This control panel operates the run on timer for the reverse pulse dust collector.

Pneumatic Distribution Panel

Pneumatic Distribution Panel

The Pneumatic Distribution Panel manages the air supplied to the; Dust collectors reverse pulse cleaning system, Pinch valve actuation, Silo cone aerators and any pneumatic vibrators. Customised boxes are made for each installation, A standard build contains:

- Pressure Regulator for Dust Collector Reverse Pulsing (Set to 6 Bar Maximum).

- Regulator / Solenoid for Aerators (Set to 1 Bar Maximum).

- Regulator / Solenoid for Pinch Valves (Set to 6 Bar Maximum).

- Indicator display – Open / Close for each Pinch Valve.

- Labeling – Standard trefalyte Black text on White background.

- Cabinet is fully plumbed and leak tested internally.

- 12mm Push in fittings for airline outlets positioned at the bottom of the Enclosure.

Vigilex Explosion Panels

Vigilex Explosion Panels

Filquip is an Australian Distributor of Vigilex Explosion Protection Panels.

- Available many rectangular, square and round sizes.

- EPDM or Silicon Food Grade Gasket Options.

- Stainless Steel Construction.

WAM Silotop Dust Collector

WAM Silotop Dust Collector

The Silotop is a cylindrical shaped dust collector designed specifically for mounting on silos.

- Filtration surface area of 24.5m².

- Compact size of 800mm diameter in a Stainless steel body.

- Maintenance free automatic reverse air jet cleaning of the cartridges.

- The Silotop is compliant with the most advanced health and safety standards.

TOREX ILT Level Indicators

Filquip is a supplier of Rotating paddle level indicators. These are available in TOREX models:

- ILTRO – Multi Voltage with rotation control

- ILTD – 24 VDC

- ILTCO – 240 VAC

- ILTA – 24 VAC

- Available with extension kits to suit any silo or hopper high or low level requirements (Standard 300, 600, 800, 1000mm).

- IP66 enclosure protection available.

WAM Pressure Relief Valves

WAM Pressure Relief Valves

Filquip can supply Spring-loaded (VCP) and Membrane (VHS) pressure relief valves to provide a safety net when abnormal pressure conditions develop in the silo, hopper or bin.

- Excess Pressure up to 900 mm H2O at a flow rate of 5,000m³/hour.

- Vacuum/Negative Pressure up to -50 mm H2O at a flow rate of 1,900m³/hour.

- Both VCP Spring-loaded and VHS Membrane Pressure Relief Valves are available in Stainless Steel of Polymer.

- Available with Duct to Ground emissions spigot.

TOREX IP Pressure Sensors

Filquip is proud to supply the TOREX IPE Electronic Pressure Meter & IPM Mechanical Pressure Meter for monitoring of the pressure inside bins or silos during their filling and the purging of tankers.

- The pressure sensor membrane is self-cleaning and temperature resistant.

- The casing is aluminium alloy with IP55 protection rating.

- Available with 4-20 mA output signal configurations for IPE.

- 24VDC supply voltage.

- IPX mounting spigot available for simple installation onto any silo.

TOREX Pinch Valves VM

TOREX Pinch Valves VM

The TOREX pinch valve provides a valve seal which does not impede pneumatic conveying flow and is not as affected by the abrasive wear of pneumatic conveying.

- Available in sizes 0.5”, 0.75”, 1”, 1.25”, 1.5”, 2”, 2.5”, 3”, 4”, 5”, 6” and 8” diameter.

- Industrial or Food Grade Versions.

The pinch valve is operated by introducing compressed air into the threaded bore of the valve interior, the internal flexible sleeve is shaped to hermetically seal the passage.

View the Pinch Valves specifications datasheet and brochure

Wear Elbows – Extrabend

Wear Elbows – Extrabend

Filquip provides a short radius wear bends with WAM patented geometry enabling diversion of the flow of the material at minimum wear.

Available in 2″, 3″ and 4″ Line sizes.

View the SINT Wear Bends specifications datasheet and brochure

Wear Bends – Extracurve

Wear Bends – Extracurve

Filquip provides long radius wear bends made from patented WAM SINT engineering polymer cast around a helicoid spring core. The symmetric nature of the wear bends allows them to be mounted in reverse when they begin to show signs of wear from abrasive materials.

Available in 2″, 3″ and 4″ Line sizes.

View the SINT Wear Bends specifications datasheet and brochure

Eurac Pipe Couplings

Eurac Pipe Couplings

Filquip is an Australian distributor for Eurac clamps for pipe and tube.

- Sizing from 38.1mm to 300mm in diameter.

- Suitable for all pneumatic and vacuum conveying operations.

- High working pressure.

- Available in Galvanised steel with Stainless Steel contact parts or in full Stainless Steel.

- NBR seals supplied as standard, other options includes FDA approved food grade, Viton and Silicon seals.

Silo Ducting & Venting

Silo Ducting & Venting

As part of the overfill protection package the following standard ducting components are supplied to vent the dust collector and pressure relief valve.

- 3 off Galvanised Spiral Ducting 0.8mm x 152mm Dia x 6 m.

- 2 off 90° Pressed Bend 150mm Dia.

- 1 off 45° Pressed Bend 150mm Dia.

- 1 off Y Piece 150mm Dia.

- 3 off Male Joiner 150mm Dia.

- 3 off Saddle Mount Hangers Suit 150mm Ducting.

Custom configurations for any silo type can be provided.

Filter Regulators, Valves, Airline & Fittings

Filter Regulators, Valves, Airline & Fittings

As part of the overfill protection package, Filquip supplies the following equipment and instrumentation for a fully operational system:

- UV stabilised nylon Airline from 6mm to 16mm (12mm Standard).

- Push in fittings for all airline sizes with connections from 1/8” to 1/2”including straight connectors, swivel bends, swivel & union tees etc.

- Filter regulators, gauges, mounting brackets and shut off valves in 1/4”, 3/8” and 1/2” fittings.

- Solenoids in 2/2, 3/2 and 5/2 configuration for air control in any voltage (Typically 24VDC, 24VAC, 240V & 110V).