Filquip offers a range of Solids-Liquids Separators designed to turn Biogas digestate from waste into a valuable resource. The Biogas SEPCOM unit turns the solids phase of the digestate into an odourless organic fertiliser / soil conditioner. While the liquid phase turns into an enriched liquid fertiliser, which can also be used for recirculation in the Biogas facility.

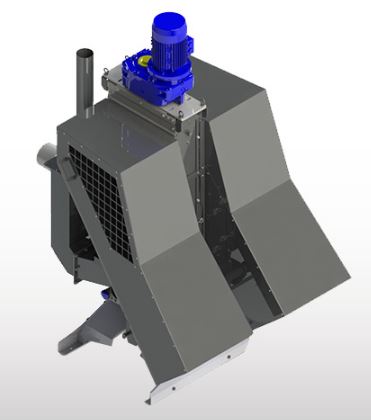

Vertical Biogas Liquid Separator SEPCOM

Vertical Biogas Liquid Separator SEPCOM

The Vertical Biogas Liquid Separator SEPCOM unit is specifically designed for dewatering Biogas plants producing irregular shaped digestate low in fibre.

The separation and conveying section of the unit consists of two vertical counter rotating conveyor screws inside a screen which lets the liquid phase pass while the conveyor screws lift the solid phase up into the compacting module.

The compacting module consists of a pressure diaphragm that compacts the solid material which is then discharged through the twin outlet chutes.

- Up to 28% dry matter.

- Never loses its solid plug.

- Includes a balance tank for stable feeding.

- The special shape of the screen chamber facilitates self cleaning.

- Available in 3 sizes: DN150 for 20m3/hr throughput , DN200 for 45 m3/hr throughtput and DN250 for up to 65 m3/hr throughput.

- Available in screen sizes down to 250 microns.

- The vertical Biogas Liquid Separator SEPCOM has a small footprint for simple integration into an existing facility.

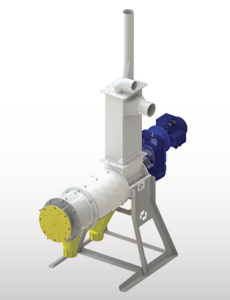

Horizontal Biogas Liquid Separator SEPCOM

Horizontal Biogas Liquid Separator SEPCOM

The Horizontal Biogas Liquid Separator SEPCOM unit is ideal for dewatering fibrous Biogas digestate such as that from corn silage and cow manure.

The unit consists of a feeding section provided with a compensator tank and overflow hopper. The stainless steel casing houses a screw conveyor and a cylindrical screen basket that conveys and separates the solids from the liquid phase flowing through the screen. The solid fraction is pushed towards the pressure diaphragm outlet where a material plug forms. This enables automatic operation of the separator preventing the liquid phase from flushing through.

- Up to 30% Separated solids.

- Self adjusting solids outlet pressure for safe continuous operation.

- Available in 3 sizes: DN150 for 20m3/hr throughput , DN260 for 45 m3/hr throughtput and DN260L for up to 65 m3/hr throughput.

- Available in screen sizes down to 250 microns.

Biogas Solids-Liquids Separator SPECO Microfilter MFT

Biogas Solids-Liquids Separator SPECO Microfilter MFT

The MFT Microfilter is designed to be integrated into a filtration system to allow filtration of the liquid phase down to a micro level.

The SEPCOM MFT Microfilter is used for the micro-screening of the liquid phase from a previous separation process of slurry or digestate from Biogas generation processes or waste water from industrial processes. It can be applied in all water purification processes.

The unit consists of a motor which drives the specially designed internal screening tool producing the force required for micro screening. The screen retains the solid phase which is expelled through the top of the machine to the outlet. The intensity of the pumping effect is used to increase separation efficiency.

- Available in screen sizes of 0.015, 0.025 & 0.05mm.

- Self Cleaning Design.

- Throughput capacity of 10m³ / hour with fluids containing less than 10% dry material.

- SEPCOM Submersible Chopper Pumps and Agitators are also available.

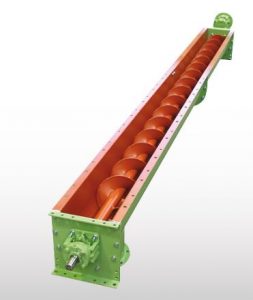

WAM Shaftless Screw Conveyors

WAM Shaftless Screw Conveyors

Filquip supplies a large range of WAM trough shaftless screw conveyors.

- Trough screw diameters of 150, 200, 250, 300, 350, 400, 500 and 600mm.

- Numerous inlet and outlet options including spigot, round and square flanges and universal.

- Standard or custom built screw conveyors including options for multiple inlets and outlets, liners and wear bars, reversible operation and with inspection hatches as required.

- Throughputs of up to 100m³ / hr.