Filquip supplies a range of Savi primary mechanical bar screens for sewage treatment plant inlet works.

The SAVI range of Mechanical bar screens are manufactured with a perforated plate or bar filter to capture screenings which are then lifted to the screens outlet with automated brushes and wiper blades.

- SAVI GVF – Mechanical vertical bar screens (Industrial Medium/Fine screenings).

- SAVI GVB – Mechanical vertical bar screens (Medium / Coarse screenings).

- SAVI GVS – Mechanical vertical Perforated Filter screens (Fine screenings).

- SAVI GVL – Low Cost Mechanical vertical bar screens (Industrial Medium screenings).

Savi GVF Mechanical Bar Screens – Fine Screening

Savi GVF Mechanical Bar Screens – Fine Screening

The Savi GVF Fine Mechanical Bar Screen is a sub-vertical primary screen for sewage treatment and industrial waste water treatment plants.

The GVF series of inlet works mechanical bar screens are installed into the flow channel and work by capturing the screening on the units bars, Chain driven mechanical rakes clean the bars by pulling the screenings up to the head of the unit to the discharge chute. A wiper system assists in removing the screenings from the rakes during discharge.

- Allows for installation in very deep channels.

- Channel widths from 400mm to 2,000mm wide.

- Discharge height from the bottom of the channel up to 7000mm.

- Mechanical bar spacing’s between 6mm and 10mm.

- 75 degree inclined angle for operation. 90 degree option available with goose neck.

- The lower bronze bushes are fully enclosed in a sealed casing for reduced maintenance.

- Available in Stainless Steel 304 or 316.

Open GVF Mechanical Bar Screens Brochure

Savi GVB Mechanical Bar Screens – Coarse Screening

Savi GVB Mechanical Bar Screens – Coarse Screening

The Savi GVB Coarse Mechanical Bar Screen is a sub-vertical primary screen for municipal and industrial waste water treatment plants.

The GVB series of mechanical bar screens are installed into the flow channel and work by capturing the screening on the units bars, Chain driven mechanical rakes clean the bars by pulling the screenings up to the head of the unit to the discharge chute. A wiper system assists in removing the screenings from the rakes during discharge.

- Allows for installation in very deep channels.

- Channel widths from 400mm to 2,000mm wide.

- Discharge height from the bottom of the channel up to 7000mm.

- Mechanical bar spacing’s of 12mm to 50mm.

- 75 degree inclined angle for operation. 90 degree option available with goose neck.

- Recessed guide channel for drive chain.

- Lower chain guide with no moving parts.

- No lower sprocket or lower bearings.

- Available in Stainless Steel 304 or 316.

Open GVB Mechanical Bar Screens Brochure

Savi GVS Mechanical Perforated Screens – Fine Screening

Savi GVS Mechanical Perforated Screens – Fine Screening

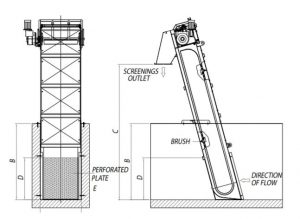

The Savi GVS Fine Perforated Mechanical Screens are a sub-vertical primary screen for municipal and industrial waste water treatment plants.

The GVS series of mechanical screens are installed into the flow channel and work by capturing the screening on the perforated plate filter, chain driven mechanical brushes and wiper blades clean the screen by pulling the screenings up to the head of the unit to the discharge chute.

- Perforated filter holes sizing from 3mm – 6mm.

- Allows for installation in very deep channels.

- Channel widths from 400mm to 2,000mm wide.

- Discharge height from the bottom of the channel up to 7000mm.

- 75 degree inclined angle for operation. 90 degree option available with goose neck.

- Four or more cleaning blades and wipers per screen depending on screen height.

- Recessed guide channel for drive chain.

- Lower chain guide with no moving parts.

- No lower sprocket or lower bearings.

- Available in Stainless Steel 304 or 316.

Open GVS Mechanical Screens Brochure

Savi GVL – Low Cost Coarse Mechanical Bar Screens

Savi GVL – Low Cost Coarse Mechanical Bar Screens

The Savi GVL Mechanical Screen consists of a steel frame and a bar filter with a galvanized steel chain transmission shaft and upper sprocket. The filtration zone contains an individually replaceable bar section. GVL screens are used for coarse screening in both municipal and industrial waste water plants.

Waste water flows into the upstream end of the unit where screenings are captured on the bars. Chain driven mechanical rakes clean the bars and convey the solids to the discharge point. There material is removed from the rakes by a wiper and discharged into a dumpster, conveyor or compactor.

The GVL model was developed with the aim of obtaining a highly industrialised product to new standards that combine renowned Savi reliability (due to thousands of installations of bar screens during the last 25 years) with low purchase, management and maintenance costs.

- Channel widths from 400mm to 2,000mm wide.

- Discharge height from the bottom of the channel up to 7000mm.

- Mechanical bar spacing’s of 10mm to 40mm.

- 75 degree inclined angle for operation.

- Recessed guide channel for drive chain.

- Recessed lower chain guide with no lower sprocket or lower bearings.

Open GVS Mechanical Screens Brochure