Ship Loader Dust Extraction System

Filquip has supplied and commissioned a Ship Loader Dust Extraction System for the Townsville Port.

The following equipment package was supplied by Filquip:

- 54m2 Bag Type Insertable Dust Collector.

- Integrated 11kw Fanset.

This Dust Extraction system which has been fitted to the ship loader at the port is an insertable model that fits directly onto the casing of the ship loader to keep all the dust within the unit and return the dust onto the process to minimise product waste.

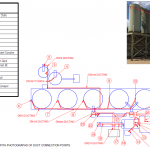

IECEX Sugar Dust Extraction Systems

Filquip has specified, supplied and commissioned three Hazardous Area Sugar Dust Extraction systems for a new refinery project. These Dust Extractors were provided with Pneumatic Driven timers to meet the tight Dust Hazardous Zoning requirements.

The following equipment package was supplied by Filquip:

- White Sugar Dust Extraction – Polygonal FPHTXM22 Dust Collector.

- Icing Sugar Dust Extraction – Round FNXM4J16 Dust Collector.

- Waste Product Dust Extraction – Round FNS3J22 Dust Collector.

These three sugar dust extraction systems have been supplied with IECEX Components for all Dust Extractor parts that are inside the hazardous area zone.

PVC Bin Filling and Dust Extraction System

Filquip has designed, supplied, installed and commissioned a PVC Resin Bin Filling and Dust Extraction System to receive pneumatically conveyed PVC resin powder, separate the pvc dust from the convyeing air and dispense the PVC resin into Tote bins while extracting the dust generated during the bin filling.

The following Filquip equipment package was provided for the PVC Resin Dust Extraction and Bin Filling System:

- Two FNW4J48 Stainless Steel Dust Collectors with 22m2 of Antistatic Filters

- One FNS4J47 Dust Extractor with 5.5kW Fanset

- Galvanised Tote Bin Filling Station Frame

- Two SS304 3m3 Hoppers with Pressure Relief Valves and Actuated Valves

Sand Silica Dust Extraction System

Filquip has designed, supplied and commissioned a Sand Silica Dust Extraction System for a Sand processing facility in Queensland. The system was designed following a Silica Dust Extraction Audit completed at the site by Filquip and draws from 23 Dust producing ports across the plant to the single Dust Extraction Unit.

The following Filquip equipment package was provided for the Sand Silica Dust Extraction System:

- FPHTU54 Dust Extractor with 54m2 of Hydrophobic and Oleophbic Treated Polyester Needle Felt Bag Filters and 11kw Fanset

- RVR05.10 8 pocket rotary valve with tips and 0.55kw Motor

- Support Subframe for a waste dust bulk bag, allowing easy disposal of captured dust

- Ducting Design Package and Bill of Materials for the client to self supply ducting

Concrete Dust Extraction System

Filquip has designed, fabricated, installed and commissioned a Concrete Dust Extraction System with hood to contain and extract the for the operators who finish grind the ends of concrete pipes. The high velocity nature of the dust emitted from the concrete grinder resulted in Filquip implementing a specific hood design to capture the dust.

The following Filquip equipment package was provided for the Bentonite pneumatic conveying system:

- FPHTU54 Dust Extractor with 54m2 of Polyester Needle Felt Bag Filters and 11kw Fanset

- Design layout, supply and installation of spiral wound ducting for extraction layout

- Filquip designed Stainless Steel Dust Capture and Extraction hood with Industrial Rubber Skirting

Hazardous Area IECEX Brewery Grain Dust Extraction

Filquip has designed, supplied, installed and commissioned a Brewery Grain Dust Extraction System which is compliant with Hazardous Area and IECEX requirements. The system extracts the dust generated in the Brewery Grain Storage Silos and Hand Grain Additive Stations and collects it through an Explosion Rated Rotary Valve seal into a Bulk Bag.

The following Filquip equipment package was provided for the Hazardous Area IECEX Brewery Grain Dust Extraction System:

- FNS3J22X Dust Collector Zone 21 Hazardous Area rated, 22m2 of Antistatic Filters with IECEX 2.2kW Fanset.

- Bulk Bag Structural Support frame to fill bulk bags with waste dust collected.

- Flameless Explosion Protection Vent and Explosion Protection Non-Return Dust Valve.

- Ducting supply and installation to the dust extraction points required.

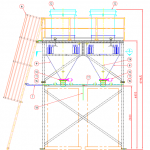

Concrete Batch Plant Load Bay Dust Extractor

Filquip has designed and supplied a Concrete Batch Plant Load Bay Dust Extractor System.

The project brief required the designed Dust extractor system to return all dust captured from the two load bay hoods into the one Flyash silo and work in with the existing load bay hoods.

The following Filquip equipment was provided by Filquip:

- Two FPHTU54 Dust Extractors with 54m2 of Polyester Needle Felt Bag Filters and twin 11kw Fansets. Inclusive of automated MDPE differential pressure reverse pulse cleaning.

Animal Feed Additive Powders Dust Extraction System

Filquip has designed, supplied, installed and commissioned a Dust Extraction system with manual isolation valves to extract from two animal feed additive weighing stations and one tote bin filling station.

The following Filquip equipment package was provided for the customer to provide their dust extraction solution:

- One FNS4J44 Stainless Steel Dust Collector with 44m2 of Antistatic, Oil and Water Resistant Filters with 4kw Fanset.

- One DK Mounting Hopper with 50L Bin and Seal Kit for collecting waste dust

- Three manual V2FS Butterfly Valves for the plant operator to isolate the dust extraction zones

- Spiral ducting, joiners, bends, support brackets for installation and commissioning of the system.