Filquip has been providing Hopper and Silo Filling Systems including Silo pressure relief valves for over 20 years for all types of powders and granular materials.

The WAM VHS and VCP Silo Pressure relief valves provide a safety net when abnormal pressure conditions endanger the silo structure. With hundreds of thousands installed worldwide, WAM Pressure Relief Valves are the standardised reliable solution for almost any silo application.

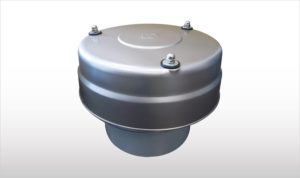

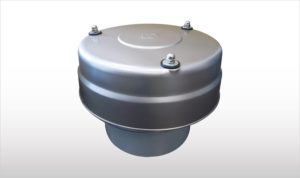

WAM VHS-B Membrane Silo Pressure Relief Valves (PRV)

WAM VHS-B Membrane Silo Pressure Relief Valves (PRV)

Filquip supply WAM VHS membrane silo pressure relief valves to provide a safety net when abnormal pressure conditions endanger the silo structure.

The VHS Pressure Relief Valves consist of a cylindrical shaped stainless steel body with clamped connection spigot to the silo, an exhaust outlet spout for duct to ground connection, an elastic membrane which is able to re-establish pressure balance instantaneously, a counterweight kit to keep the valve closed under normal conditions, and a weather protection cover.

Through an interplay of pressure on both sides of the membrane fitted inside the valve a perfect pressure balance is achieved. In the event of excess pressure the membrane enables air from inside the silo to flow out into the atmosphere, whereas in case of suction vacuum pressure opens the membrane to the atmosphere to allow air in to prevent silo collapse.

- Excess Pressure up to 900 mm H2O at a flow rate of 5,000m³/hour (0.09 Bar or 1.3 PSI at 2,950 cfm).

- Vacuum/Negative Pressure up to -50 mm H2O at a flow rate of 1,900m³/hour (-0.005 Bar or -0.07 PSI).

- Stainless Steel 304 Casing with Mild Steel or Stainless Steel Upstand to connect to your silo.

- Casing Diameter 273mm

- Available with Duct to Ground kit.

- Food Grade Versions Available.

Open VHS Stainless Steel Pressure Relief Valve Brochure

WAM VCP Spring-Loaded Silo Pressure Relief Valves (PRV)

WAM VCP Spring-Loaded Silo Pressure Relief Valves (PRV)

Filquip supply WAM VCP spring loaded silo pressure relief valves to handle sudden excess or suction pressures that can develop in the silo, hopper or bin.

The VCP Pressure Relief Valves consist of a cylindrical shaped stainless steel casing with bottom flange to connect to the silo, an inner negative pressure disc held in position by a central spring rod, an outer positive pressure steel ring kept in position by three spring rods, and a weather protection cover.

Preset springs keep the valve closed when the pressure inside the silo remains within the preset limits. Once the pressure exceeds the preset value the outer ring is pushed up and pressure can escape. In the event of vacuum pressure the spring is compressed and allows the inner disc to drop. The air entering the silo from outside ensures rapid pressure balancing and before the spring pushes the inner disc back up into “closed” position.

- Excess Pressure up to 800 mm H2O at a flow rate of 13,000m³/hour (0.05 Bar or 0.72 PSI at 7,650 cfm).

- Vacuum/Negative Pressure up to -100 mm H2O at a flow rate of 1,900m³/hour (-0.01 Bar or -0.14 PSI).

- Painted Carbon Steel or Stainless Steel 304 Casing with Mild Steel or Stainless Steel Upstand to connect to your silo.

- Casing Diameter 273mm (10 inch) or the larger 356mm (14 inch) model.

- Available with inductive sensor for an output signal when the valve is activated.

- Food Grade Versions Available.

Open VCP Spring Loaded Pressure Relief Valve Brochure

WAM VHS-C Polymer Membrane Silo Pressure Relief Valves (PRV)

WAM VHS-C Polymer Membrane Silo Pressure Relief Valves (PRV)

Filquip supply WAM VHS-C Polymer membrane silo pressure relief valves to ensure the filling of a silo does not allow abnormal pressure conditions to endanger the silo structure.

The VHS-C Pressure Relief Valves consist of a cylindrical shaped polymer body with flanged connection spigot to the silo, an exhaust outlet spout for duct to ground connection, an elastic membrane which is able to re-establish pressure balance instantaneously, a counterweight kit to keep the valve closed under normal conditions, and a weather protection cover.

Through an interplay of pressure on both sides of the membrane fitted inside the valve a perfect pressure balance is achieved. In the event of excess pressure the membrane enables air from inside the silo to flow out into the atmosphere, whereas in case of suction vacuum pressure opens the membrane to the atmosphere to allow air in to prevent silo collapse.

- Excess Pressure up to 500 mm H2O at a flow rate of 5,000m³/hour (0.05 Bar or 0.72 PSI at 2,950 cfm).

- Vacuum/Negative Pressure up to -50 mm H2O at a flow rate of 1,900m³/hour (-0.005 Bar or -0.07 PSI).

- Polymer Casing with Mild Steel or Stainless Steel Upstand to connect to your silo.

- Casing Diameter 273mm (10 inch).

- Counterweight system never in contact with dust.

- Special properties of membrane and elbow prevent clogging and formation of material crusts.

- Available with Duct to Ground kit.

- Food Grade Versions Available.

- Available with inductive sensor for an output signal when the valve is activated.

Open VHS-C Polymer Pressure Relief Valve Brochure

WAM VCP-D Spring-Loaded Polymer Silo Pressure Relief Valves (PRV)

WAM VCP-D Spring-Loaded Polymer Silo Pressure Relief Valves (PRV)

Filquip supply WAM VCP-D spring loaded silo pressure relief valves made from polymer are built to handle sudden excess or suction pressures that can develop in the silo, hopper or bin.

The VCP-D Pressure Relief Valves consist of a cylindrical casing made from engineered polymer with bottom flange to connect to the silo, an inner negative pressure disc held in position by a central spring rod, an outer positive pressure steel ring kept in position by three spring rods, and a weather protection cover.

Preset springs keep the valve closed when the pressure inside the silo remains within the preset limits. Once the pressure exceeds the preset value the outer ring is pushed up and pressure can escape. In the event of vacuum pressure the spring is compressed and allows the inner disc to drop. The air entering the silo from outside ensures rapid pressure balancing and before the spring pushes the inner disc back up into “closed” position.

- Excess Pressure up to 500 mm H2O at a flow rate of 6,000m³/hour (0.05 Bar or 0.72 PSI at 3,531 cfm).

- Vacuum/Negative Pressure up to -50 mm H2O at a flow rate of 1,900m³/hour (-0.005 Bar or -0.07 PSI).

- Polymer Casing with Mild Steel or Stainless Steel Upstand to connect to your silo.

- Casing Diameter 273mm (10 inch).

- Available with inductive sensor for an output signal when the valve is activated.

- Food Grade Versions Available.

Open VCP-DPolymer Spring Loaded Silo Pressure Relief Valve Brochure

Silo Overfill Protection System

Silo Overfill Protection System

Filquip can supply a tailored silo overfill protection system to suit any system, to prevent dangerous over pressurisation and over filling, while eliminating dust emissions.

- Avoid damage to silo and accessories.

- Reduce the risk of air pollutions.

- Eliminate the risk of filling the incorrect silo.

- Start and stop the filter cleaner automatically.

- Systems can be tailored to suit applications including the need for Pressure monitoring, Over pressure or vacuum release valves, Fill control, Dust control and Operator destination selection panel.

Open Silo Overfill Protection System Page