Hazardous Area IECEX Sugar Dense Phase Conveying

Filquip has specified, supplied and commissioned a Hazardous Area IECEX Sugar Dense Phase Conveying to transport 6TPH of sugar a distance of 270m between the existing sugar refinery and the new sugar processing facility on the other side of the plant.

The following equipment package was supplied by Filquip:

- Full Pipeline Dense Phase System for White Sugar 12TPA600 FP Model.

- 1699L Vessel Capacity, Hazardous Zone 21 Rated, IECEX Certified Instruments.

- Inclusive of Electrical Control and Air Control Panels and Pipeline Air Boosters.

- Receiver Silo Explosion Protection Panel (s).

Given the hazardous area dust explosion risks associated with Sugar handling. Filquip supplied this Dense Phase system with IECEX Zone 21 Rated Instrumentation and components rated to 10 bar pressure which is above the maximum explosion pressure of sugar.

Hazardous Area IECEX Icing Sugar Vacuum Conveying System

Filquip has specified, supplied and commissioned a Hazardous Area IECEX Icing Sugar Vacuum Conveying System to transport 6TPH of Icing sugar a distance of 35m between the milled icing sugar storage hopper and the icing sugar packing machine storage bin.

The following equipment package was supplied by Filquip:

- 30kW Vacuum Blower System with Acoustic Enclosure.

- Drop Through Rotary Valve (Model RVS20.20, SS304, 1.1kW IECEX Motor).

- Six Borosilicate Glass Long Radius Bends (101.6mm OD, 500mm radius).

- Rotary Valve to Tube Venturi Transition Chute.

- Hepa Filter Intake Filter Box.

- Receiver Silo Explosion Protection Panel (s).

Given the hazardous area dust explosion risks associated with icing sugar. Filquip supplied this vacuum conveying system with IECEX Zone 21 Rated Instrumentation and ATEX rated mechanical equipment such as rotary valves and dust collectors which were specified with compliant Explosion Resistant Pred pressure specifications to match the sized explosion protection panels.

Hazardous Area IECEX Brewery Grain Vacuum Conveying System

Filquip has specified, supplied, installed and commissioned a Hazardous Area IECEX Brewery Grain Vacuum Conveying System. The design transports 2.5TPH of malted barley brewery grain using a vacuum conveying system which draws the product from one of two storage silos and transports it 30m through a number of bends into the brewery mill.

The following equipment package was supplied and Installed by Filquip:

- 5kW Vacuum Blower System.

- Three Drop Through Rotary Valve (Model RVR02.20, 0.55kW IECEX EXtD Motor).

- Two Borosilicate Sight Glasses (50.mm OD, 500mm long).

- Vacuum Receiver Separator Filter with Hopper (FNS3J22D).

- Receiver Silo Explosion Protection Panel(s).

- Receiver Load Cells for weighing product into the mill.

- System control box and HMI for inputting the desired weight of grain to be vacuum conveyed and milled.

Given the hazardous area dust explosion risks associated with grain handling. Filquip supplied this vacuum conveying system with IECEX Zone 21 Rated Instrumentation and ATEX rated mechanical equipment such as rotary valves and dust collectors which were specified with compliant Explosion Resistant Pred pressure specifications to match the sized explosion protection panels.

Hazardous Area IECEX Sugar Dust Extraction Systems

Filquip has specified, supplied and commissioned three Hazardous Area Sugar Dust Extraction systems for a new refinery project. These Dust Extractors were provided with Pneumatic Driven timers to meet the tight Dust Hazardous Zoning requirements.

The following equipment package was supplied by Filquip:

- White Sugar Dust Extraction – Polygonal FPHTXM22 Dust Collector.

- Icing Sugar Dust Extraction – Round FNXM4J16 Dust Collector.

- Waste Product Dust Extraction – Round FNS3J22 Dust Collector.

These three sugar dust extraction systems have been supplied with IECEX Components for all Dust Extractor parts that are inside the hazardous area zone.

Hazardous Area IECEX Brewery Grain Dust Extraction

Filquip has designed, supplied, installed and commissioned a Brewery Grain Dust Extraction System whcih is compliant with Hazardoua Area and IECEX requirements. The system extracts the dust generated in the Brewery Grain Storage Silos and Hand Grain Additive Stations and collects it through an Explosion Rated Rotary Valve seal into a Bulk Bag.

The following Filquip equipment package was provided for the Hazardous Area IECEX Brewery Grain Dust Extraction System:

- FNS3J22X Dust Collector Zone 21 Hazardous Area rated, 22m2 of Antistatic Filters with IECEX 2.2kW Fanset.

- Bulk Bag Structural Support frame to fill bulk bags with waste dust collected.

- Flameless Explosion Protection Vent and Explosion Protection Non-Return Dust Valve.

- Ducting supply and installation to the dust extraction points required.

Hazardous Area IECEX Starch Bulk Bag Unloader

Filquip has specified, supplied and commissioned a new Hazardous Area IECEX Starch Bulk Bag Unloader with bag massaging system.

The following specifications were included for the Starch Bulk Bag Unloader:

- Forklift Loadable Bulk Bag Unloader Model SBB.125.

- Stainless Steel 304 Contact Parts, Painted Mild Steel Frame.

- 2m3 Hopper Capacity with Level Prove and Vent Outlet.

- Pneumatic Cylinder Massaging System.

- Access door proximity switch

This Starch Bulk Bag Unloader was built and supplied with IECEX electrical parts and instrumentation for all equipment located inside the hazardous area zone.

Hazardous Area IECEX Starch Handling System

Filquip was awarded the contract for the Design and Construction of a Hazardous Area IECEX Starch Handling System for Unloading, Storing and Conveying the Starch products.

The following equipment package was supplied, installed and commissioned:

- Starch Storage Silo (70m³ Capacity, Painted Mild Steel).

- Silo Dust Vent.

- Silo Explosion Panels.

- Silo Overfill Protection System (PRV, Control Panel, Level Sensor, Vibrator, Valves).

- Lean Phase Conveying System with Tri-Lobe Blower.

- Two Bulk Bag Unloaders (Model SBB.125, Painted Mild Steel).

- Intermediate Hopper (1m3).

- Horizontal & Vertical Screw Conveyors (1500mm & 4500mm Long).

The experience of Filquip with handling starch and the dust explosion hazards associated with it gives our customers the confidence to trust Filquip to their bulk powders and granules handling projects.

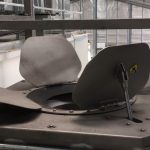

Hazardous Area IECEX Grain Loading Bellows

Filquip has specified, supplied and commissioned a new set of Hazardous Area IECEX Grain Loading Bellows to fill/load open trucks with grain from bulk storage silos.

The following specifications were included for the Loading Bellows:

- 55kW IECEX Winch Motor.

- IECEX Junction Box and IECEX Level Indicators for Control Feedback.

- Inner and Outer Bellows system (No drop cones).

- Stroke of 3000mm (4830mm extended length, 1830mm retracted length).

- 440 m3/hr Throughput Capacity.

Given the hazardous area dust explosion risks associated with grain handling. Filquip supplied this loading bellow system with IECEX Zone 21 Rated Instrumentation located inside the hazardous area zone.