Filquip is an Australian Distributor of Vigilex Explosion protection panels for Silos and Hoppers. Manufactured in France to the highest quality, every Vigilex Panel comes with a conformity certificate of testing from the batch of panels in which it was produced.

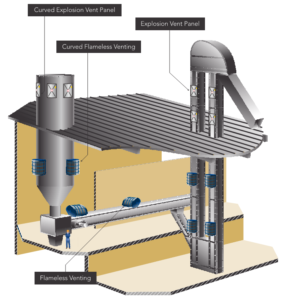

Explosion venting is a vital safeguard for your plant from the consequences of an explosion. Knowing what explosion protection equipment your mill, dryer, cyclone, filter or Silo needs is key.

Filquip also holds various standard sized Vigilex Explosion panels in stock in Brisbane, Australia.

Open the Full Vigilex Explosion Protection Brochure

Vigilex VL Single Flat Explosion Protection Panels

Vigilex VL Single Flat Explosion Protection Panels

The VL series Explosion Protection Panels are suitable for low vacuum or working pressure applications such as Bucket Elevators, Conveyors, Silos and Cyclones.

They have an integral flange for simple installation with a wide gasket providing a dustproof seal.

- Available many rectangular, square and round sizes.

- Standard EPDM (-40 Deg C to +80 Deg C) or Silicon Food Grade Gasket (-60 Deg C to +200 Deg C) Options.

- Stainless Steel 304 or Optional Stainless Steel 316.

- Optional Graphite Gasket Available (-200 Deg C to +500 Deg C).

Open the Vigilex VL Explosion Protection Panel Brochure

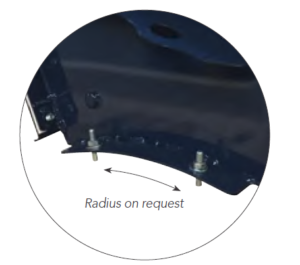

Vigilex VL-R Single Curved Explosion Protection Panels

Vigilex VL-R Single Curved Explosion Protection Panels

The VL-R series or curved Explosion Protection Panels are curved to the customers specifications and batch tested after being formed to ensure the correct burst pressure has been delivered. They are suitable for low vacuum or working pressure applications such as Bucket Elevators, Conveyors, Silos and Cyclones.

They have an integral flange for simple installation with a wide gasket providing a dustproof seal.

- Available many rectangular and square sizes to a curved radius as requested.

- Standard EPDM (-40 Deg C to +80 Deg C) or Silicon Food Grade Gasket (-60 Deg C to +200 Deg C) Options.

- Stainless Steel 304 or Optional Stainless Steel 316.

- Optional Graphite Gasket Available (-200 Deg C to +500 Deg C).

Open the Vigilex VL-R Curved Explosion Protection Panel Brochure

Vigilex VL-S Single Flat Inexpensive Explosion Panels

Vigilex VL-S Single Flat Inexpensive Explosion Panels

The VL-S series of Explosion Protection Panels have been designed to be low cost for low vacuum or working pressure applications such as Bucket Elevators, Conveyors, Silos and Cyclones. They are provided with a gasket to cover the breaking points.

- Available many rectangular, square and round sizes.

- Standard Black EPDM or Silicon Food Grade Gasket Options.

- Stainless Steel 304 or Optional Stainless Steel 316.

- Optional +500 Deg C Carbon Gasket Available

Open the Vigilex VL-S Inexpensive Explosion Protection Panel Brochure

Vigilex EHEDG Hygenic Explosion Panels

Vigilex EHEDG Hygenic Explosion Panels

The EHEDG Hygenic series Explosion Protection Panels have been especially designed for the food and pharmaceutical industries. They are certified hygenic by the European Hygienic Engineering & Design Group (EHEDG). These Hygenic Explosion Protection Panels are suitable for low vacuum or working pressure applications.

They have an integral flange for simple installation with a patented and certified hygenic gasket providing a dustproof seal.

- Silicon FDA approved Food Grade Gasket (-60 Deg C to +200 Deg C).

- Stainless Steel 316 Construction.

- Clean Design with Bacteriological barrier.

Open the Vigilex EHEDG Hygenic Explosion Protection Panel Brochure

Vigilex VD Single Domed Explosion Protection Panels

Vigilex VD Single Domed Explosion Protection Panels

The VD Vacuum Resistant Pressure series Explosion Protection Panels are designed to protect equipment that operates under negative pressures or with pulsating processes. The domed design is suitable for Dust Collectors, Filters, Silos and Cyclones subjected to fluctuating pressures and vibrations.

They have an integral flange for simple installation with a wide gasket providing a dustproof seal.

- Available many rectangular, square and round sizes.

- Standard EPDM (-40 Deg C to +80 Deg C) or Silicon Food Grade Gasket (-60 Deg C to +200 Deg C) Options.

- Stainless Steel 304 or Optional Stainless Steel 316.

- Optional Graphite Gasket Available (-200 Deg C to +500 Deg C).

Open the Vigilex VD Vacuum Resistant Explosion Protection Panel Brochure

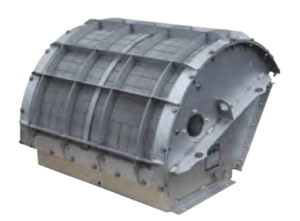

Vigilex VD-HV Single Domed High-Vacuum Resistance Explosion

Vigilex VD-HV Single Domed High-Vacuum Resistance Explosion

The VD-HV Vacuum Resistant Pressure series Explosion Protection Panels are an extra strong ribbed design to protect equipment that operates under negative pressures or with pulsating processes. The domed design is suitable for Dust Collectors, Filters, Silos and Cyclones subjected to fluctuating pressures and vibrations.

They have an integral flange for simple installation with a wide gasket providing a dustproof seal.

- Available many rectangular, square and round sizes.

- Standard EPDM (-40 Deg C to +80 Deg C) or Silicon Food Grade Gasket (-60 Deg C to +200 Deg C) Options.

- Stainless Steel 304 or Optional Stainless Steel 316.

- Optional Graphite Gasket Available (-200 Deg C to +500 Deg C).

Open the Vigilex VD-HV Strong Vacuum Resistant Explosion Protection Panel Brochure

Vigilex VQ Flameless Explosion Venting Panel

Vigilex VQ Flameless Explosion Venting Panel

The VQ Flameless Explosion Venting Panel systems are a safe venting solution for protection of equipment indoors and outdoors where a flame cannot escape. Hazardous area or equipment near where personnel may be are covered by the VQ Flameless Vents.

The VQ Flameless Vent provides effective low pressure resistance to eliminate the spread of the flame and hot particles. It is essentially a flame arresting case comprising or a porous and heat-absorbing surface. The vented explosion enters the box and the gases are cooled as they pass through the porous surface, dust is filtered out and the flame is quenched. The internal surface area of the Vigilex Flameless vent is designed so that the effective vent area is almost the same as if the vent itself was free.

- Available is a wide range of square and rectangular sizes.

- Mild steel body and casing with Stainless Steel Mesh. Optional Stainless Steel body available.

- Burst Sensor Model SEC Included

- Available in a Variety of Colours

Open the Vigilex VQ Flameless Explosion Venting Brochure

Vigilex VQ-R Curved Flameless Explosion Venting

Vigilex VQ-R Curved Flameless Explosion Venting

The VQ-R Curved Flameless Explosion Venting Panel systems are a safe venting solution for protection of equipment indoors and outdoors where a flame cannot escape. Hazardous area or equipment near where personnel may be are covered by the VQ Flameless Vents.

The curved flameless device can be installed directly onto Cylindrical Hoppers or Silos. This avoids the possibility of material settling in front of the explosion panel.

The VQ Flameless Vent provides effective low pressure resistance to eliminate the spread of the flame and hot particles. It is essentially a flame arresting case comprising or a porous and heat-absorbing surface.

- Available many rectangular and square sizes to a curved radius as requested.

- Mild steel body and casing with Stainless Steel Mesh. Optional Stainless Steel body available.

- Burst Sensor Model SEC Included

- Available in a Variety of Colours

Open the Vigilex VQ-R Flameless Explosion Venting Brochure

Vigilex VQ Metal Dusts Explosion Flameless Venting

Vigilex VQ Metal Dusts Explosion Flameless Venting

The VQ Flameless Explosion Venting Panel for Metal Dusts are certified to protect all facilities, equipment and machinery which process combustible metals.

The VQ Metal Dusts Design ensures maximum resistance to the high temperatures generated by a metal dust fire and the explosion.

It is essentially a flame arresting case comprising or a porous and heat-absorbing surface. The vented explosion enters the box and the gases are cooled as they pass through the porous surface, dust is filtered out and the flame is quenched.

- Available many rectangular and square sizes to a curved radius as requested.

- Mild steel body and casing with Stainless Steel Mesh. Optional Stainless Steel body available.

- Burst Sensor Model SEC Included

- Available in a Variety of Colours

Open the Vigilex VQ Metal Dusts Flameless Explosion Venting Brochure

Explosion Panels – Accessories

Explosion Panels – Accessories

Filquip is an Australian Distributor of Vigilex Explosion Protection Panels and accessories including:

- MEC – Mechanical Burst Sensor 12 – 240 VAC or VDC

- MAG – Magnetic Burst Sensor 12 – 60 VDC

- SEC – Break Cable Sensor 1.5 VDC Output (100mA, 25 mW)

- IND – Inductive Proximity Sensor 12 – 48 VDC

- Vigilex TI – Thermal insulation for Explosion panels

- Vigilex WI – Weather protection from wind, snow, hail and dirt for explosion panel.

- Vigilex CAP – Discharge duct for explosion panels in Stainless or Galvanised Steel.

- Vigilex GS/GD – Fall protection grids to fit inside panel area.