Lime Bulk Bag Unloader

Filquip has specified, supplied, installed and commissioned numerous Lime Lime Bulk Bag Unloaders including one included in a mobile lime dosing system.

The following Filquip equipment package was provided as part of this project to handle lime bulk bags and create a milk of lime slurry for lime dosing:

- A telescopic Bulk Bag Unloading System with Stainless Steel 304 Product Contact Parts.

- One TU168.2700 Inclined Screw Conveyor, 150mm diameter, 2.7m long in Painted Mild Steel.

- One 500L Milk of Lime mixing tank with 0.55kw Agitator

- One Dust Extraction unit with 1.1kw Fanset and 0.55kw Rotary Valve to contain and return lime dust to the process.

Calcium Carbonate Bulk Bag Unloader

Filquip has specified, supplied, installed and commissioned Calcium Carbonate Bulk Bag Unloaders including this case study for a dry building materials packaging plant.

The following Filquip equipment package was provided as part of this calcium carbonate bulk bag handling system:

- One (1) SBB.125 Bulk Bag Unloader, Full Frame Build with Lifting Cross and Hopper Low Level Indicator.

- One (1) AT273.1200 Horizontal Screw Conveyor, 250mm diameter, 1.2m long in Painted Mild Steel.

- One (1) VE273.4000 Vertical Screw Conveyor, 250mm diameter, 4m long in Painted Mild Steel.

Starch Bulk Bag Unloader

Filquip has specified, supplied and commissioned a new Starch Bulk Bag Unloader with bag massaging system.

The following specifications were included for the Starch Bulk Bag Unloader:

- Forklift Loadable Bulk Bag Unloader Model SBB.125.

- Stainless Steel 304 Contact Parts, Painted Mild Steel Frame.

- 2m3 Hopper Capacity with Level Prove and Vent Outlet.

- Pneumatic Cylinder Massaging System.

This Starch Bulk Bag Unloader was built and supplied with IECEX electrical parts for all equipment located inside the hazardous area zone.

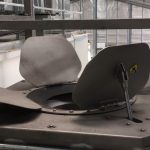

Mobile Bulk Bag Unloaders

Filquip has designed, fabricated and supplied a range of Mobile Bulk Bag Unloader systems with bag splitters and integrated screw conveyor to decant to products.

The following equipment package was designed, supplied and commissioned:

- Hard wearing bag splitting knife.

- 1m3 Storage Hopper with Electric Vibrator for product flow.

- Modular Screw Conveyor (De-mountable for transport or storage).

- Local control panel, wired ready for use to the motors.

The technical experience of Filquip has allowed us to develop a range of mobile bulk bag unloaders with Loading Bellows and Integrated Dust Extraction options also available.

PE Beads Bulk Bag Unloader

Filquip has specified, supplied, installed and commissioned a number of PE Beads Bulk Bag Unloaders which can also accept container tipping systems for delivery of the PE beads.

The following Filquip equipment package was provided as part of this mobile PE bead bulk bag unloader and container unloader system:

- Telescopic Bulk Bag Unloader Frame to decant PE beads from Bulk Bags

- 30kW Positive Pressure Blower with Acoustic Enclosure

- Truck Connection spout to fill beads into the same skid system

- Rotary Valve (Model RV35.20, SS304, 1.5kW Motor, Capacity 33m3/hr)

- Galvanised Skid and SS304 Piping Fork-Liftable (4800 x 1600mm)

- Local Control Panel (MCC and PLC) all prewired with Local Junction Box

Cement Bulk Bag Unloader

Filquip has specified, supplied, installed and commissioned numerous Cement Bulk Bag Unloaders including one included in a mobile lime dosing system.

The following Filquip equipment package was provided as part of this mobile fly ash and cement bulk bag unloader system:

- Fabricated 1m3 Bulk Bag Unloader with Bag Cutting Blades

- Electric Hopper Vibrator

- Hopper Lump Breaker

- Pre-Wired Plug and Play Electrical Control Panel with 20m 3phase cord and plug

- One ES273.7200 Inclined Screw Conveyor, 250mm diameter, 7.2m long in Painted Mild Steel.

Polymer Bulk Bag Unloader

Filquip has specified, supplied, installed and commissioned Flocculant or Polymer Bulk Bag Unloaders including this case study for a Polymer Unloading and Dosing System:

The following Filquip equipment package was provided as part of this Polymer Handling System:

- Bulk Bag Unloader with Monorail and Hoist Crane with lockable access doors.

- Storage Hopper with Dust Extractor System.

- Horizontal to Vertical Screw Conveyor System for handling the Polymer.

- Polymer batching tank with agitator.

PAC Bulk Bag Unloader

Filquip has specified, supplied, installed and commissioned a number of PPAC Bulk Bag Unloaders including this PAC plant system for this case study profile.

The following Filquip equipment package was provided as part of this Powder Activated Carbon dosing system package:

- Bulk Bag Unloader (Model SBB.125, Painted Mild Steel, Monorail Structure with Electric Hoist)

- Horizontal to Vertical Screw Conveyor System for handling the Polymer.

- 3m3 Bulk Storage Hopper (3m3).

- Two Microbatch Volumetric Feeders (MBF073A 1.8L/min – 15L/min).

- Round FS2J13 Dust Collector (13m2 Cartridge Unit).