Filquip offers a range of Compactors for Industrial use in compacting Screenings, Animal Manure, Kava, Tapioca, Paper Pulp, Winery grape waste, Plastics, Rubber, Cattle Rumen, Offal, Brewery Wastes, Sludge, Sewage, Vegetables, Fruit and most other soft wastes.

CHP Hydraulic Compactors

CHP Hydraulic Compactors

The CHP Hydraulic Compactors range use a hydraulic ram to compact materials in municipal and industrial applications.

The unit consists of a inlet hopper which moves product into the compaction zone. The hydraulic ram dewaters and pushes screenings into the compacting pipe where they are further compressed and conveyed to the outlet. Any liquid that is squeezed out of the product is drained through the lower part of the compactor.

- Available in Hot Galvanized, Stainless Steel 304 or Stainless Steel 316 constructions.

- Available in 3 sizes for compaction throughputs of 1.5 m³ / hr to 3.5 m³ / hr.

- Up to a 60% reduction in materials volume.

- Small footprint unit.

Open CHP Hydraulic Compactors Brochure

Screw Compactors / Screenings Compactors VWP

Screw Compactors / Screenings Compactors VWP

The VWP Shafted Compactors are used to compact screenings in municipal and industrial waste plants.

The unit consists of a compaction inlet hopper which feeds the thick shafted steel auger which rotates inside the compacting zone to squeeze and convey the screenings while dewatering them.

- Available in Stainless Steel 304 or Stainless Steel 316 constructions.

- Available in 3 sizes for compaction throughputs of 1.5 m³ / hr to 6 m³ / hr.

- Up to a 65% reduction in materials volume.

- Small footprint unit.

Open VWP Screw / Screenings Compactors Brochure

Open VWP Screw / Screenings Compactors Datasheet

Wastecom CPS Solids Dewatering Screw Compactor

Wastecom CPS Solids Dewatering Screw Compactor

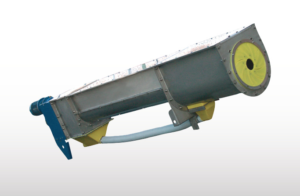

The CPS Wastecom is a Dewatering Screw Compactor built for use in industrial applications.

The unit consists of a conveyor trough manufactured from stainless steel with a heavy duty screw spiral feeding the solids into the dewatering compaction module.

The Speco CPS Screw Compactor provides three functions in the one unit: conveying, de-watering and compacting. They can be employed in various de-watering applications and in combination with different types of solids-liquid separators or conveyors. They are generally used in industrial applications for compacting various solids from different processes (Municipal/Industrial waste water treatment, Food processing, Slaughterhouses/Abattoirs, Rock wool industries, Plastics recycling processes and many more).

- Available in Stainless Steel 304 or Stainless Steel 316 constructions.

- Includes a replaceable trough liner from from Low Friction HDPE Polymer.

- Special design for not intermediate or outlet bearings.

- Up to a 40% reduction in screenings volume.

- Low noise levels and low energy consumption.

Open SEPCOM CPS Solids Dewatering Screw Compactor Brochure

Screenings Washer Compactors VWP WM

Screenings Washer Compactors VWP WM

The VWP WM Shafted Screenings Washer Compactors are used to compact and wash screenings in municipal and industrial waste plants.

The unit consists of a washing hopper with an impeller that separates the solid screenings from the organic matter, which feeds the thick shafted steel auger which rotates inside the compacting zone to squeeze and convey the screenings while washing out the organic content and dewatering them.

- Available in Stainless Steel 304 or Stainless Steel 316 constructions.

- Available in 3 sizes for compaction throughputs of 1.5 m³ / hr to 6 m³ / hr.

- Up to a 65% reduction in materials volume.

- Small footprint unit.

Open VWP WM Screw / Screenings Washer Compactors Brochure

EXTRAC Bag Compactors COM

EXTRAC Bag Compactors COM

For disposing of large volumes of empty bags the COM Waste Bag Compactor is an efficient and economical solution. Bags are compressed to a fraction of their original volume while the workplace is kept perfectly tidy.

The COM Bag Compactor for broken empty bags consists of a trough that is longitudinally split in half to facilitate replacement of the SINT liner that helps with the introduction of the bags into the compression chamber and further compression of the broken bags once in the chamber. At the end of the COM outlet a polyethylene tube for disposal of waste bags can be fitted.

The COM Waste Bag Compactor can receive entire empty bags or bag fragments from a bag emptying device. It compacts bags to approximately one eighth of their original volume. Waste bags can be easily disposed of by collecting them in a polyethylene hose which has to be periodically cut and sealed.

- Available in Carbon Steel or Stainless Steel 304

- All models come with heavy duty shaftless spiral with bearing mounted at the inlet.

- Easy access to all parts due to its modular design.

- Able to handle bags of different sizes without machine adjustment (Not large bulk bags).

- Available in Hazardous Area Zone build.

- The bag compactor does not have to be shut down to release the filled outlet bag.

Open Waste Bag Compactors Brochure

Shaftless Screw Conveyors SSC

Shaftless Screw Conveyors SSC

Filquip supplies a large range of WAM trough screw conveyors available in shafted and shaftless configurations including and high temperature options.

- Trough screw diameters of 150, 200, 250, 300, 350, 400, 500 and 600mm.

- Numerous inlet and outlet options including spigot, round and square flanges and universal.

- Standard or custom built screw conveyors including options for multiple inlets and outlets, liners and wear bars, reversible operation and with inspection hatches as required.

- Throughputs of up to 100m³ / hr.

Open Shaftless Spiral Conveyor