Filquip supplies MAP Industrial Mixers made in Italy. MAP mixers are the global standard in mixing solids, granules, powders, chemicals, food products, waste, cement and building materials.

Open General MAP Industrial Mixers Brochure

Filquip has access to the worldwide network of MAP Mixers Laboratories to perform mixing testing and ensure the best mixing practices and results are obtained for your required recipe.

MAP Continuous Single Shaft Industrial Mixers – WAH Model

MAP Continuous Single Shaft Industrial Mixers – WAH Model

The WAH Continuous Single Shaft Industrial Mixers are the ideal machine to obtain highest quality mixtures. Mixing with WAH is quick yet gentle with thousands of mixers supplied over the last three decades all over the world.

WAH Continuous Industrial Mixers consist of a cylindrical mixing drum with an inlet at one end, an outlet at the opposite end and a venting spout. With internal mixing shaft, two drum closing end plates with flanged end bearing assemblies complete with integrated air or gas-purged shaft seals, and a drive unit complete with power transmission the WAH mixer is built to industrial standards.

Ploughshares or inclined blade-type shovels rotate as mixing tools in a specific arrangement on the mixer shaft inside the drum vessel. The result is a specific turbulence through the mix that constantly brings all the product particles into the mixing process removing the formation of dead spots or slow-movement zones.

- Model sizes with capacities from 2m³/hr to 1,000m³/hr.

- Ability to add up to 20% liquid to the continuous mixing process.

- End bearing assemblies available with various types of air or nitrogen-purged shaft seals or grease sealing.

- Available in Carbon Steel, Anti-wear steel, Stainless Steel 304 and Stainless Steel 316 constructions.

- Available in bead blasted, mirror polished or grit silked finishes.

- Wide range of mixing tools fittable including ploughshare, toothed ploughshare, blade-type, toothed blade all possible with anti-wear coating on request.

- Available with Replaceable liners, Ceramic liners, Teflon liners and Stainless steel mesh as optional additions.

- Optional pneumatic sampling devices available to be fitted.

Open MAP WAH Continuous Single Shaft Mixers Brochure

MAP Batch Single Shaft Industrial Mixers – WBH Model

MAP Batch Single Shaft Industrial Mixers – WBH Model

The WBH Batch type Single Shaft Industrial Mixers are the ideal machine to obtain highest quality mixtures in perfectly reproducible batches. MAP also provides mixing tests for customers in the companies own laboratories currently in more than fifteen countries.

WBH Horizontal Single Shaft Batch Mixers consist of a mixing drum with an inlet, an outlet with discharge valve and a venting spout, a full material mixing shaft, two drum closing end plates that carry flanged end bearing assemblies complete with integrated air or gas-purged shaft seals, and a drive unit complete with power transmission.

The WBH Batch Industrial Mixer is based on the principle of mechanical fluidisation of the product.

The specific shape, position and rotation speed of the mixing tools, creates a centrifugal vortex motion which moves the materials in a three-dimensional way to merge with each other. This ensures that ingredients with different particle sizes and bulk densities are perfectly blended and mixed with high precision within the shortest time possible.

WBH Batch-type Mixers are used for mixing dry powders, granules or short fibres, for moistening, agglomerating or granulating the same materials, or for mixing liquids or low viscosity pastes.

- Model sizes with capacities from 10L/batch to 20,000L/batch.

- Variation Co-efficient achieved (CV) of 3 to 5%.

- Ability to add up to 20% liquid to the batch mixing process.

- End bearing assemblies available with various types of air or nitrogen-purged shaft seals or grease sealing.

- Available in Carbon Steel, Anti-wear steel, Stainless Steel 304 and Stainless Steel 316 constructions.

- Available in bead blasted, mirror polished or grit silked finishes.

- Wide range of mixing tools fittable including ploughshare, toothed ploughshare, blade-type, toothed blade all possible with anti-wear coating on request.

- Available with Replaceable liners, Ceramic liners, Teflon liners and Stainless steel mesh as optional additions.

- Optional pneumatic sampling devices available to be fitted.

Open MAP WBH Batch Single Shaft Mixers Brochure

MAP Tubular Batch Type Ribbon Blenders – WBN Model

MAP Tubular Batch Type Ribbon Blenders – WBN Model

The WBN Batch Type Ribbon Blender is the ideal mixer to obtain high quality results with fragile materials, with its slowly turning single shaft double counter-pitch ribbon screw it is able to conserve the physical properties of the products being mixed.

WBN Ribbon Blenders consist of a horizontal, single shaft double counter-pitch ribbon screw housed in a tubular mixing drum. They have a central inlet or a rectangular inlet port over the entire length of the mixing drum, an outlet with central discharge outlet, a venting spout, two drum closing end plates complete with integrated air or gas-purged shaft seals, and a drive unit complete with power transmission.

The ribbon outer helix moves the material from both ends of the vessel towards the centre, while the inner helix cycles the material towards both ends, this action results in a convective mixing process where the products are gently processed in a relatively short mixing time.

Typically Batch-type WBN Ribbon Blenders are used for mixing dry PVC, dry powders or granules in general, as well as liquids and low-viscosity pastes.

- Model sizes with capacities from 10L/hr to 20,000L/hr.

- Mixing times from 5min to 15min generally

- End bearing assemblies available with various types of air or nitrogen-purged shaft seals or grease sealing.

- Available in Carbon Steel, Stainless Steel 304 and Stainless Steel 316 constructions.

- Available in bead blasted, mirror polished or grit silked finishes.

- Optional additional liquid supply equipment.

- Optional pneumatic sampling devices available to be fitted.

Open MAP WBN Batch Ribbon Blender Mixers Brochure

MAP Batch Bombay doors mixers – WBHT & WBHP Models

MAP Batch Bombay doors mixers – WBHT & WBHP Models

The MAP Bomb-Bay Discharge Batch Industrial Mixers of the WBHP type with 15° opening cross section and the WBHT type with a 60° opening satisfy any customer’s requirements in terms of high quality mixing in a batch-type processes with optimised efficiency. An outlet opening over the entire length of the mixing drum ensures almost residue-free discharge of the product in the shortest possible time.

In addition to the features of standard WBH mixers, the WBHP and WBHT-type ensure instant product discharge with residue of less than 0.1% depending on the product mixed.

WBHP / WBHT Bomb-Bay Door Batch Mixers are the appropriate mixing machines for virtually all industries (building and construction, food, animal feed, chemicals, etc.) where the highest possible mixing quality and optimum productivity are required.

- Model sizes with capacities from 165L/batch to 20,000L/batch.

- Variation Co-efficient achieved (CV) of 3 to 5%.

- Ability to add up to 20% liquid to the batch mixing process.

- End bearing assemblies available with various types of air or nitrogen-purged shaft seals or grease sealing.

- Available in Carbon Steel, Anti-wear steel, Stainless Steel 304 and Stainless Steel 316 constructions.

- Available in bead blasted, mirror polished or grit silked finishes.

- Wide range of mixing tools fittable including ploughshare, toothed ploughshare, blade-type, toothed blade all possible with anti-wear coating on request.

- Available with Replaceable liners, Ceramic liners, Teflon liners and Stainless steel mesh as optional additions.

- Optional pneumatic sampling devices available to be fitted.

Open MAP WBHT / WBHP Batch Mixers with Bombay Doors Brochure

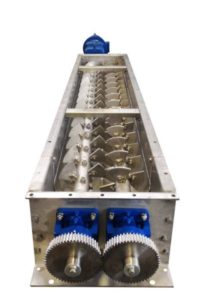

MAP Continuous Twin Shaft Screw Mixers – MESC Model

MAP Continuous Twin Shaft Screw Mixers – MESC Model

The MESC Twin Shaft Paddle Screw Mixer (Available as a MESC-UM as conditioner with liquid injection) is among the most efficient yet economic mixer types when it comes to rapid mixing and conditioning of products when mix homogeneity is now the paramount concern.

MESC-type Twin Shaft Paddle Mixers are equipped with two parallel counter-rotating, intermeshing paddle shafts. The adjustable angle of inclination of the mixing paddles allows perfect adaptation to different material characteristics and mixing process requirements.

Twin Shaft Paddle Screw Mixers are used for powder mixing, sludge granulation and neutralisation, as well as for dust, ash, or sludge conditioning.

- Model sizes with capacities from 3m³/hr to 70m³/hr.

- Ability to add up to 20% liquid to the continuous mixing process.

- Available in Carbon Steel, Anti-wear steel, Stainless Steel 304 and Stainless Steel 316 constructions.

- Available with Replaceable liners, Ceramic liners, Teflon liners and Stainless steel mesh as optional additions.

Open MAP MESC Continuous Paddle Screw Industrial Mixers Brochure

MAP Laboratory Mixers – MLH Model

MAP Laboratory Mixers – MLH Model

The MLH is a highly versatile and efficient yet affordable laboratory mixer. University researchers and test laboratories from virtually all industries an both utilise the MLH to test mixing process and product feasibility.

The MLH Laboratory Batch Mixer consists of stand-alone drive unit with incorporated frequency inverter, an easily replaceable horizontal mixing shaft supported at the drive end only, and an easily replaceable revolving mixing vessel complete with inlet/outlet. It has an inspection door ensuring free access to all internal parts and is equipped with a variety of mixing tools. The MLH machine produces high quality mixtures which are reproducible over time.

The MAP Laboratory Batch Mixers operate on the principle of a mechanically generated fluid bed, as such laboratory results can be transferred to production units. This ensures the product and process development that is required by today’s industry is met. In some cases, to obtain the desired mixing effect, a separately driven high-speed chopper can be installed.

MLH is a Laboratory Batch Mixer suitable for applications in the pharmaceutical, food, chemical, biochemical, and powder metallurgy industries.

- Available in three vessel sizes; 6L, 12L and 30L.

- Mixing times from 5min to 15min generally

- Available in Stainless Steel 304 or Stainless Steel 316 constructions.

- Easily replaceable mixing shaft.

- No product deterioration of damage.

- Wide range of mixing tools (ploughshare, toothed ploughshare, blade-type, toothed blade, ribbon), available with anti-wear coating on request

- Optional additional liquid supply equipment.

- Optional pneumatic sampling devices available to be fitted.

- Available with mirror polished or Teflon liner finish.

- Available in a jacketed mixing chamber for heating or cooling.

Open MAP MLH Laboratory Mixers Brochure

MAP Mortar Mixers

MAP Mortar Mixers

Filquip is a supplier of mortar mixers with bag feed and silo feed options

- The Wetmix V05 is a continuous horizontal single shaft mixer for fitting under a silo in the preparation of premixed mortars or plasters.

- The Wetmix bag unit is a horizontal single shaft mixer suitable for all dry premixed building materials delivered on bags such as mortars, plasters, slags and adhesives.

MAP Dust Conditioners

MAP Dust Conditioners

The Wetdust and Dustfix Dust Conditioners provide an economical solution for conditioning industrial dusts.

It is the ideal machine for the evacuation, conditioning and disposal of dusts, in all industries. Due to its particular technical features, its innovative design and extremely short processing time, DUSTFIX enables dust-free discharging of products into open trucks or onto belt conveyors.

- Suitable for dust recycling, storage or disposal.

- Developed for handling the most abrasive industrial quarry return pit dusts.

- Throughput rates up to 80m³ per hour.

- Dust conditioning chamber manufactured from special non-stick anti-wear SINT engineering polymer.

Open Dust Conditioners Brochure

Low Profile Circular Lump Breaker LBC

Low Profile Circular Lump Breaker LBC

The WAM LBC Circular Lump Breaker is a low profile cost effective solution to clumps and lumps in powders and granular materials.

- Lump Breaker body manufactured in Aluminium Alloy and available with Stainless Steel or Mild Steel Blades.

- Available in multiple diameters including 200, 250, 300, 350 and 400mm.

- 75mm Flange to Flange (Low Profile).

- Comes with Gearbox and Motor.