Filquip is a provider of MAP Dust Conditioners for the effective mixing of dusts and powders with liquids. Manufactured for conditioning and disposal of dusts in all industries. They enables dust-free discharging to open trucks or belt conveyors.

MAP Dust Conditioners – Dustfix

MAP Dust Conditioners – Dustfix

The Wetdust and Dustfix Dust Conditioners provide an economical solution for conditioning industrial dusts.

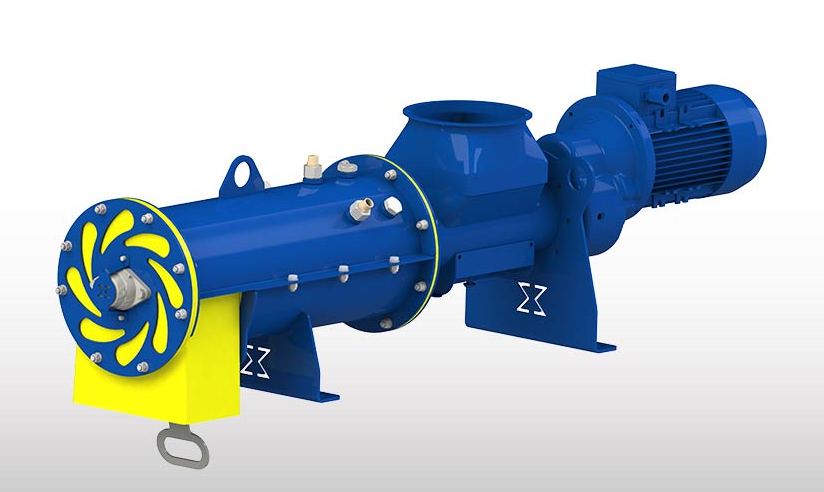

It is the ideal machine for the evacuation, conditioning and disposal of dusts, in all industries. Due to its particular technical features, its innovative design and extremely short processing time, DUSTFIX enables dust-free discharging of products into open trucks or onto belt conveyors.

The Dustfix Dust Conditioner consists of a carbon steel tubular housing with SINT polymer liner, a combined feeder screw/mixing shaft, one vertical inlet and a SINT vertical outlet, a liquid supply point in the conditioning section, and a drive unit with integrated shaft seal.

- Throughput rates up to 80m³ per hour.

- Suitable for dust recycling, storage or disposal.

- Developed for handling the most abrasive industrial quarry return pit dusts.

- Rotor shaft is modular with replaceable conditioning tools.

- Dust conditioning chamber manufactured from special non-stick anti-wear SINT engineering polymer.

Open Dustfix Dust Conditioners Brochure

MAP Dust Conditioners – Wetdust

MAP Dust Conditioners – Wetdust

The Wetdust Dust Conditioners provide an economical solution for conditioning industrial dusts.

It is the ideal machine for the evacuation, conditioning and disposal of dusts, in all industries. Due to its particular technical features, its innovative design and extremely short processing time, WETDUST enables dust-free discharging of products into open trucks or onto belt conveyors.

The Wetdust Dust Conditioners consist of a steel tubular housing with SINT polymer liner, a combined feeder screw/mixing shaft entirely manufactured from SINT polymer, one vertical inlet and a vertical outlet, a liquid supply point in the conditioning section, as well as a drive unit with integrated adjustable shaft seal.

- Throughput rates up to 6m³ per hour.

- Suitable for dust recycling, storage or disposal.

- Developed for handling the most abrasive industrial quarry return pit dusts.

- Rotor shaft is modular with replaceable conditioning tools.

- Dust conditioning chamber manufactured from special non-stick anti-wear SINT engineering polymer.

Open Wetdust Dust Conditioners Brochure

MAP Mortar Mixers

MAP Mortar Mixers

Filquip is a supplier of mortar mixers with bag feed and silo feed options

- The Wetmix V05 is a continuous horizontal single shaft mixer for fitting under a silo in the preparation of premixed mortars or plasters.

- The Wetmix bag unit is a horizontal single shaft mixer suitable for all dry premixed building materials delivered on bags such as mortars, plasters, slags and adhesives.

MAP Dust Conditioners – Claygran

MAP Dust Conditioners – Claygran

The Claygran Dust Conditioners provide an economical solution for conditioning ceramic dusts.

The Claygran Dust Conditioners represent the most economical solution to the problem of disposal of dust from filtration in ceramics processing plants. Thanks to its particular technical features, innovative materials and quick processing time, Claygran is suitable for continuous heavy-duty processes.

- Throughput rates up to 6m³ per hour.

- Suitable for dust recycling, storage or disposal.

- Developed for handling the most abrasive industrial quarry return pit dusts.

- Rotor shaft is modular with replaceable conditioning tools.

- Dust conditioning chamber manufactured from special non-stick anti-wear SINT engineering polymer.

- Simple cleaning and effective wear protection