Filquip has been providing hopper and silo discharging systems for over 17 years for all types of powders and granular materials.

Pneumatic Conveying

Pneumatic Conveying

Filquip has specialist experience in Lean phase blowing, Dense phase conveying and Vacuum conveying systems.

EXTRAC Bin Activator

EXTRAC Bin Activator

The EXTRAC Bin Activator is a silo or bin discharging device that creates controlled vibration in middle of the product column for continuous extraction with optimal mass flow.

- Available in Stainless steel 304, Carbon steel or Carbon steel with food grade paint.

- Seamless discharge cone.

- ATEX Zone 21 & 22 certified versions available.

- Gasket made from wear-resistant SINT engineering polymer.

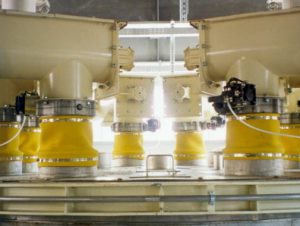

WAM Live Silo/Bin Bottoms MU

WAM Live Silo/Bin Bottoms MU

MU Live Bin Bottoms are the ideal solution for discharging particularly difficult materials from polygonal hoppers or silos.

- Used for extracting biological or industrial sludge, paper scrap, wood chippings, sawdust, flour, bran, chemical pellets and many other products.

- Up to 6 shafted helicoid flight or paddle screws for product movement.

- Screw diameters from 150 to 600mm and trough length from 1,500 to 4,000mm.

- Available in Carbon steel or Stainless steel

TOREX Outloading / Loading Bellows

The TOREX telescopic loading bellows range has been developed for efficient dust free loading and unloading of powders and granular materials.

The TOREX telescopic loading bellows range has been developed for efficient dust free loading and unloading of powders and granular materials.

- Available in Open truck, Tanker, Drum and Ship options.

- Throughput capacity from 1m³ to 1,800m³ / hr across the product range.

- ATEX Zone 20-22 and 20-21 versions available.

- Operating temperatures from -40°C to 150°C.

EXTRAC Lump Breakers

EXTRAC Lump Breakers

Filquip provides a range of lump breakers and crumblers for breaking up lumpy materials.

- Twin shaft for high throughput rates.

- Available in Carbon steel, Stainless steel 304 & 316.

- Throughputs up to 50m³ / hr.

TOREX Rotary Valves

TOREX Rotary Valves

Filquip provides a range of TOREX rotary valves to meter solids from a hopper or silo, place into a blower pneumatic conveying system or provide an airlock on a dust collector.

- Drop through and Blow through options in Cast iron, Stainless Steel 304 & 316, Chromed, Teflon and Nickel plated.

- Round inlet diameters of 150,200,250 & 300mm.

- Square inlet dimensions of 150,200,250 & 300mm.

- Rectangular inlet dimensions of 170×122, 238×135, 276×148, 377×196, 470×240 & 569x284mm.

- Capacities of 2, 5, 10, 20, 35 & 80 L/Rev.

- Working Temperatures from -40°C to 150°C.

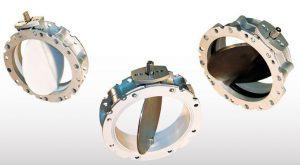

WAM Butterfly Valves

WAM Butterfly Valves

Filquip supplies a range of butterfly valves for materials handling systems.

- Valve pressure rating options of up to 0.2, 2.5 and 8 bar.

- Carbon steel, Aluminium alloy and Stainless steel material options.

- Manual, Pneumatic or Electrical actuation options available.

- Size options of 100, 125, 150, 175, 200, 250, 300, 350 & 400mm diameter.

EXTRAC Bulk Bag Unloader SBB

EXTRAC Bulk Bag Unloader SBB

The EXTRAC SBB Bulk Bag unloader provides an effective solution to unloading bulk bags of product in an efficient manner.

- Available in a half frame height where a crane or forklift is utilised to lift and hold the bag during unloading.

- Available in full frame height with telescopic rails for bag loading into the frame.

- Includes a vibrating pan plate and dust collection point to ensure efficient and clean bulk bag unloading.

- Optional bag massagers available for hard to move materials.

- Bulk Bag Unloaders are available in Carbon steel, Stainless steel 304 and Stainless steel 316.

Open SBB Bulk Bag Unloader Brochure

WAM Slide Gate Valves

Slide gate valves are used where the flow of a bulk solid by gravity is required to be intercepted.

Slide gate valves are used where the flow of a bulk solid by gravity is required to be intercepted.

- Carbon steel and Stainless steel construction material options.

- Square cross section sizes of 150, 200, 250, 300, 350, 400, 450, 550, 650, 750 & 950mm.

- Round cross section diameters of 150, 200, 250, 300, 350 & 400mm.

- Rectangular cross section sizes of 150×250, 200×300, 250×400, 300×450, 375×560 & 425x650mm.

- Internal Actuation available and Low profile “thin” gates available.

- Manual, Pneumatic or Electrical Actuation options available.

Open VG Slide Gate Valves Brochure

Open VL Series Slide Valve Brochure

WAM Double Dump Valve VDC

WAM Double Dump Valve VDC

The WAM VDC Double Dump Valves consist of a robust casing and two alternately activated flaps, one installed on top of the other.

- An ideal solution for controlled discharging of particularly high temperature or abrasive, large particle size materials.

- Square Inlets from 200×200 to 500x500mm.

- Throughput capacities from 1.2 to 17.7m³/hr with a working temperature up to 500°C.

- Suitable for discharging dust from large de-dusting units and for heavy-duty applications in general, in virtually all industries.

Open Double Dump Valve Brochure

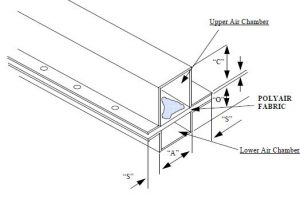

Air Slide Material

Air Slide Material

Filquip is a provider of airslide material to the bulk materials handling industry to standard dimensions and custom dimensions for your airslide.

WAM LBC Circular Lump Breaker

The new WAM LBC Circular Lump Breaker is a low profile cost effective solution to clumps and lumps in powders and granular materials.

- Circular Lump Breaker body manufactured in Aluminium Alloy and available with Stainless Steel or Mild Steel Blades.

- Available in multiple diameters including 200, 250, 300, 350 and 400mm.

- 75mm Flange to Flange (Low Profile)

- Comes with Gearbox and Motor

Open Circular Lump Breaker Operation Video

Air Slides

Air Slides

Filquip is provider of new airslide systems to the bulk materials handling industry to meet the custom dimensions for your project.

EXTRAC Bulk Bag Filler RBB

EXTRAC Bulk Bag Filler RBB

The EXTRAC RBB Bulk Bag Filler uses a steel support frame with telescopic tubes allowing height adjustment to adapt to different bulk bag dimensions.

Bulk Bag Fillers are available in Carbon steel, Stainless steel 304 and Stainless steel 316.

MAP Dust Conditioners

MAP Dust Conditioners

The MAP Wetdust and Dustfix Dust Conditioners provide an economical solution for conditioning industrial dusts.

- Suitable for dust recycling, storage or disposal.

- Developed for handling the most abrasive industrial quarry return pit dusts.

- Throughput rates up to 80m³ per hour.

Open Dust Conditioner Brochure

WAM Microbatch Feeders MBF

WAM Microbatch Feeders MBF

The WAM MBF range of Micro-batch feeders provide accurate volumetric feeding of powder and granular materials.

- Stainless steel body, Agitator tool and Feeder screw.

- Available with Horizontal or Vertical spout outlets.

- Available with food-grade and ATEX zone versions.

- Throughputs of up to 6m³ / hr.

- Integration with a loss in weight system or VSD can provide automated accurate batching systems.

Open Microbatch Feeders Brochure

Silos

Silos

Filquip can supply Welded or Bolt together silo packages including all of the required Silo “Jewellery” to Australian Standards.

- Welded Silos available in custom built heights, diameters and capacities.

- Bolt together silo options from 35m³ to 125 m³. Allowing modular construction inside a building.

Open Bolt Together Silos Brochure

Wear Elbows – Extrabend

Wear Elbows – Extrabend

Filquip provides a short radius wear bends with WAM patented geometry enabling diversion of the flow of the material at minimum wear.

Wear Bends – Extracurve

Wear Bends – Extracurve

Filquip provides a long radius wear bends made from patented WAM SINT engineering polymer cast around a helicoid spring core. The symmetric nature of the wear bends allows them to be mounted in reverse when they begin to show signs of wear from abrasive materials.

Eurac Pipe Couplings

Eurac Pipe Couplings

Filquip is an Australian distributor and agent for Eurac couplings for pipe and tube.

- Sizing from 38.1mm to 300mm in diameter.

- Suitable for all pneumatic and vacuum conveying operations.

- High working pressure.

- Available in Galvanised steel with Stainless Steel contact parts or in full 304 Stainless Steel.

- NBR seals supplied as standard, other options includes FDA approved food grade, Viton and Silicon seals.

Mobile Bulk Bag Splitting Station

Filquip has custom designed and fabricated a range of mobile bulk bag splitters with integrated screw conveyor to unload product.

Each mobile bulk bag unloading system comes with the following components:

- Hard wearing bag splitting knife.

- 1.1m3 Storage Hopper with Electric Vibrator for product flow.

- Modular Screw Conveyor (De-mountable for transport or storage).

- Local control panel, wired ready for use to the motors.