Cement Dense Phase Conveying System

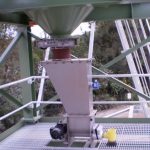

Filquip has supplied a Cement Dense Phase conveying system that has been in operation since 2012. The project involved the Design, Supply, Installation and Commissioning of a bulk bag unloading & Dense Phase transfer system for a 50m conveying distance at 35TPH.

Supply, Install and Commission Cement Unloader and Storage System:

- Dense Phase Transfer System (BART One 900 System).

- Cement Silo (100T Silo).

- Silo Overfill Protection Panel.

- Silo Dust Venting and Pressure Relief Valves.

- Loading Bellows with integrated Dust Extractor (BellowJet Model).

- Bulk Bag Unloader with cutting blades and integrated Dust Extraction System.

- Air Compressor, Air Receiver and Weather Shelter.

This bulk bag unloading & transfer system has saved the client labour time and manual handling. The dense phase unit transfers the white cement faster than the forklift operator can load the bags, minimising the time required to fill the out-loading storage silo which then fills tanker trucks.

Stone Dust Dense Phase Transfer System

Filquip has supplied and commissioned a Stone Dust Dense Phase Transfer System to convey the quarry stone dust from the air classifiers to a Storage Silo at a distance of 60m and throughput of 40TPH. Filquip also supplied a Dust Conditioning System to the Storage Silo which conditions the stone dust so it can be loaded into open trucks for return to the quarry pit.

The following equipment package was supplied:

- Dense Phase Transfer System (BART One 900 System).

- Airline Dense Phase Boosters.

- Compressed Air Receiver.

- Dust Conditioning System (Dustfix 80 Model).

This dense phase transfer system replaced a Z-Conveyor previously being used which was failing on a fortnightly basis due to the extreme abrasion of the stone dust. The BART ONE 900 provides a reliable solution which minimises the maintenance requirements of the quarry.

Mixed PVC Resins Dense Phase Conveying

Filquip has supplied a Mixed PVC Resins Dense Phase conveying system that conveys the mixed PVC from the cooler to the storage hoppers before the extrusion lines. The project involved the Design, Supply and Commissioning of a the Dense Phase systems to fit into the pit underneath the existing cooler systems and convey the PVC powders a distance of 60m at a rate of 20 TPH.

The following equipment package was supplied:

- Dense Phase Transfer System (BART One 900 System).

- Receiver Silotop Dust Collectors.

- Compressed Air Receiver.

- Dense Phase Air Supply Boosters.

This dense phase conveying system provides the customer a solution to transporting the specific mixed PVC product at 20TPH from the mixer cooler 60m to each of three Injection Silos without product stratification and reduced wear on the pipelines.

Lime Dosing System – Gibson Island WTP

Filquip was awarded the contract for the Design and Construction of the Lime Dosing System for the Gibson Island Water Treatment Plant.

The following equipment package was supplied, installed and commissioned:

- Two Lime Silos (125m3 Capacity Each).

- Lime Silo Bin Activators (One per Lime Silo).

- Two Microbatch Volumetric Feeders (MBF114 Model with Turndown Range 0.007 m3/min – 0.066 m3/min).

- Two Dosing Pumps (35 m3/hr each).

- Two Mixing Tanks (Stainless Steel 316, 12m3 volume each).

- Silo Pressure Relief Valves.

- Two Round FS4J39 Silo Dust Collectors (39m2 Cartridge Unit).

- Silo Load Cells and Weight Transmitter System.

- Silo Overfill Protection Systems.

The experience of Filquip with lime dosing systems allows us to design packages that minimise the common lime problems associated with Blockages and Scale build up.

Lime Dosing System – Bundamba WTP

Filquip was awarded the contract for the Design and Construction of the Lime Dosing System Lime Powder Handling at the Bundamba Water Treatment Plant.

The following equipment package was supplied, installed and commissioned:

- Two Lime Silos (72m3 Capacity Each).

- Lime Silo Bin Activators (One per Lime Silo).

- Two Microbatch Volumetric Feeders (MBF073A Model with Turndown Range 0.0018 m3/min – 0.015 m3/min).

- Silo Pressure Relief Valves.

- Two Round FS4J39 Silo Dust Collectors (39m2 Cartridge Unit).

- Silo Load Cells and Weight Transmitter System.

- Silo Overfill Protection Systems.

The experience of Filquip with lime dosing systems allows us to design packages that minimise the common lime problems associated with Blockages and Scale build up.

Container Unloading and Transfer System

Filquip has supplied, installed and commissioned a Container Unloading and Transfer System for Unloading Containers of PVC powders and conveying it into Storage Silos. The system has been sized to fully decant a container of PVC powder in 45 minutes.

The following equipment package was supplied:

- Container Unloading Chute and Screw Conveyor.

- Intermediate hopper between Screw Conveyor and Dense Phase Conveyor (2.2m3).

- Dense Phase Transfer System (12TPA500).

- Compressed Air Receiver

- Bulk Bag Unloader system for additional feed from bulk bags into the storage silos.

This container unloading and transfer system from Filquip saves the customer considerable cost on specialised container suck/blow unloading trucks as simple container lifting trucks can be utilised to deliver raw materials. Along with providing a dust free bulk bag unloading system giving flexibility of raw material procurement options to the company. The system transfers full 20T Container loads of PVC or Calcium Carbonate up to 60m to four different selectable silo locations in 45 minutes.

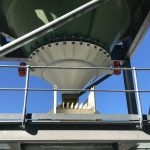

Ship Loader Dust Extraction System

Filquip has supplied and commissioned a Ship Loader Dust Extraction System for the Townsville Port.

The following equipment package was supplied:

- 54m2 Bag Type Insertable Dust Collector.

- Integrated 11kw Fanset.

This Dust Extraction system which has been fitted to the ship loader at the port is an insertable model that fits directly onto the casing of the ship loader to keep all the dust within the unit and return the dust onto the process to minimise product waste.

Cement Batch Plant Screw Conveyors

Filquip has designed, supplied and commissioned a set of four (4) ES273 Screw Conveyors 8m long each for conveying Cement and Fly ash from Silos in a Low profile Batch Plant.

The following equipment package was supplied:

- Four (4) ES273.8000 Screw Conveyors with Motors and Gearboxes.

- Silo aeration airslide media.

- Silo plan air slides media.

The use of Screw Conveyors for transfer of the batch plant products from each silo into the weigh bins reduces the overall height of the batch plant to become a “low profile” concrete batch plant.

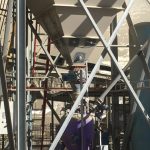

Flyash Screw Conveyors

Filquip has designed, supplied and commissioned a set of three piggy back screw conveyors for transferring FlyAsh to a loading bellow for Outloading from the power plant into tank trucks.

The following equipment package was supplied:

- Three (43) TC323.5800 Screw Conveyors with Motors and Gearboxes.

- ZAMBA Bellowjet Loading Bellows with integrated dust extractor.

- Mobile Fabricated Frames for Screw Conveyors and Loading Bellows.

The use of this mobile screw conveyor setup allows the extraction of the flyash from under the Power Plant storage hoppers and efficient dust free loading of this fly ash into tanker trucks.

PAC Dosing System – Mudgeeraba WTP

Filquip was awarded the contract for the Design and Construction of the PAC Dosing System Powder Handling at the Mudgeeraba Water Treatment Plant.

The following equipment package was supplied, installed and commissioned:

- PAC Storage Silo (15m3 Capacity).

- Silo Dust Extraction unit – Ducted into the PAC Bulk Bag Unloader.

- PAC Bulk Bag Unloader with Dust Extraction to the Storage Silo.

- VE-At Horizontal and Vertical Screw Conveyor Combination (ES219 Models)

- Microbatch Volumetric Feeder (MBF073A Model with Turndown Range 0.0018 m3/min – 0.015 m3/min).

- Silo Pressure Relief Valve.

- Silo Overfill Protection System.

This PAC unloading, storage and metering system was designed to be a small footprint system resulting the use of the Horizontal & Vertical Screw Conveyor system to fill the Storage Silo from Bulk Bags of PAC while fitting into the existing WTP facility and mixing tank.

Hydrated Lime Dosing System – Murrumba Downs WWTP

Filquip was awarded the contract for the Design and Construction of the Hydrated Lime Dosing System at the Murrumba Downs Waste Water Treatment Plant.

The following equipment package was supplied, installed and commissioned:

- Two Hydrated Lime Silos (20m3 Capacity Each).

- Hydrated Lime Silo Bin Activators (One per Lime Silo).

- Two Microbatch Volumetric Feeders (MBF042A Model with Turndown Range 0.0003 m3/min – 0.0013 m3/min).

- Silo Pressure Relief Valves.

- Two Round FS4J24 Silo Dust Extrractors (24m2 Cartridge Unit).

- Silo Load Cells and Weight Transmitter System.

- Silo Overfill Protection Systems.

The experience of Filquip with hydrated lime dosing systems allows us to design packages that minimise the common lime problems associated with Blockages and Scale build up.

Starch Handling System

Filquip was awarded the contract for the Design and Construction of a Starch Unloading, Storage and Conveying Project.

The following equipment package was supplied, installed and commissioned:

- Starch Storage Silo (70m³ Capacity, Painted Mild Steel).

- Silotop Silo Dust Vent.

- Silo Explosion Panels.

- Silo Overfill Protection System (PRV, Control Panel, Level Sensor, Vibrator, Valves).

- Lean Phase Conveying System with Tri-Lobe Blower.

- Two Bulk Bag Unloaders (Model SBB.125, Painted Mild Steel).

- Intermediate Hopper (1m3).

- Horizontal & Vertical Screw Conveyors (1500mm & 4500mm Long).

The experience of Filquip with handling starch and the dust explosion hazards associated with it gives our customers the confidence to trust Filquip to their bulk powders and granules handling projects.

Manganese Dioxide Dense Phase Conveying

Filquip has supplied and commissioned a Dense Phase Conveying System for the transport of Manganese Dioxide from Bulk Bags into a weigh hopper on the Brick Manufacturing line. The system is capable of conveying 1.5T per hour of Manganese Dioxide a distance of 20m.

The following equipment package was designed, supplied and commissioned:

- BARTONE 80 Dense Phase Conveying System (80L Vessel).

- Conveying Line Air Boosters.

The experience of Filquip with handling abrasive and difficult products such as Manganese Dioxide using Dense Phase Conveying technology provided a compact Unloading and Conveying system that could be installed into the tight space available in the operating brick manufacturing plant.

Lime Dense Phase Conveying

Filquip has supplied and commissioned a Dense Phase Conveying System for the movement of Hydrated Lime from Bulk Bags into a weigh hopper on the Brick Manufacturing line. The system is capable of conveying 1T per hour of Hydrated Lime a distance of 20m.

The following equipment package was designed, supplied and commissioned:

- BARTONE 50 Dense Phase Conveying System (50L Vessel).

- Conveying Line Air Boosters.

The experience of Filquip with handling difficult products such as Hydrated lime using Dense Phase Conveying technology provided a compact Unloading and Conveying system that could be installed into the tight space available in the operating brick manufacturing plant.

Sand Dense Phase Conveying

Filquip has supplied and commissioned a Dense Phase Conveying System for the transport of Sand from Bulk Bags into a weigh hopper on the Brick Manufacturing line. The system is capable of conveying 0.5T per hour of Sand a distance of 20m.

The following equipment package was designed, supplied and commissioned:

- BART Dense Phase Conveying System (24L Vessel).

- Conveying Line Air Boosters.

The experience of Filquip with handling abrasive such as Sand using Dense Phase Conveying technology provided a compact Unloading and Conveying system that could be installed into the tight space available in the operating brick manufacturing plant.

Centralised Industrial Vacuum System

Filquip has supplied, installed and commissioned a Centralised Industrial Vacuum System for a Flour Mill with the system running 150m in total length over 6 building floors in the plant with 20 pickup points.

The following equipment package was designed, supplied and commissioned:

- Installation of SS304 Piping, Eurac Pipe Clamps, Nozzle Heads and Wands.

- Twin 7.5kW Vacuum Blowers.

- Negative Pressure Dust Collector for the Filter Receiver (FNS3J22D).

- SS304 Support Frame – Customised to Site Location.

- Rotary Valve Airlock for vacuumed feeding product into a bulk bag (RVR05.20).

The technical experience of Filquip in sizing the pipe runs and velocities has allowed the one Centralised Industrial Vacuum System to draw from these 20 locations through the 6 levels of the plant as opposed to needing multiple Vacuum Systems to service the whole plant.

Mobile Bulk Bag Unloader

Filquip has designed, fabricated and supplied a range of Mobile Bulk Bag Unloader systems with bag splitters and integrated screw conveyor to decant to products.

The following equipment package was designed, supplied and commissioned:

- Hard wearing bag splitting knife.

- 1.1m3 Storage Hopper with Electric Vibrator for product flow.

- Modular Screw Conveyor (De-mountable for transport or storage).

- Local control panel, wired ready for use to the motors.

The technical experience of Filquip has allowed us to develop a range of mobile bulk bag unloaders with Loading Bellows and Integrated Dust Extraction options also available.

Stone Dust Conditioning System

Filquip has supplied an Asphalt plant Stone Dust Conditioning system used to load open trucks with the excess stone dust generated by the plant without the requirement for closed tanker trucks or vacuum trucks for removal.

The following equipment package was supplied by Filquip:

- Dustfix Dust Conditioner (Dustfix 40 Model, 40m3/hr capacity).

- Local control panel for system and water supply.

The use of this system has saved the Asphalt Plant operator $60,000 over the first 3 months of operation from the reduced costs of needing specialist subcontractors to remove the stone dust, the use of open top trucks is a much more cost-effective solution made possible by this Stone Dust Conditioning System.

Mobile Polyethylene Beads Transfer System

Filquip has designed, Fabricated, Supplied and Commissioned a Mobile Polyethylene Beads Transfer system to convey the PE beads from Bulk Bags or from Containers into site silos.

The following equipment package was supplied by Filquip all on a mobile skid frame:

- 30kW Positive Pressure Blower with Acoustic Enclosure.

- Half Height Bulk Bag Unloader with Truck Fitting Spout.

- Rotary Valve (Model RV35.20, SS304, 1.5kW Motor, Capacity 33m3/hr).

- Galvanised Skid and SS304 Piping Fork-Liftable (4800 x 1600mm).

- Local Control Panel (MCC and PLC) all prewired with Local Junction Box.

The use of this system has saved the customer the additional costs of the container delivery companies “Suck and Blow” Conveyor system mounted onto the truck and given them a range of product contained supplier options resulting in an annual cost saving of $200,000.

Shaftless Sludge Screw Conveyors

Filquip has designed, supplied and commissioned a set of Two reversible shaftless sludge screw conveyors to the Northpine WTP. These Sludge Screw Conveyors transfer the sludge from the Centrifuges to 3 possible outlets to fill portable bins below.

The following equipment package was supplied by Filquip:

- Two Reversible Screw Conveyors (Model SSC, DN300, SS304, 4580mm Long, 3kW).

- Two Pneumatic Slide Gates for middle screw conveyor outlet.

- Six Drop Chutes from outlets to transport sludge skips.

The modular nature of the SSC Screw Conveyor Manufacturing Process ensures that standardised parts are available for these shaftless sludge screw conveyors as opposed to custom built units which may not use standardised modular parts.

Sugar Dense Phase Conveying System

Filquip has specified, supplied and commissioned a Sugar Dense Phase Conveying System to transport 6TPH of sugar a distance of 270m between the existing sugar refinery and the new sugar processing facility on the other side of the plant.

The following equipment package was supplied by Filquip:

- Full Pipeline Dense Phase System for White Sugar 12TPA600 FP Model.

- 1699L Vessel Capacity, Hazardous Zone 21 Rated, IECEX Certified Instruments.

- Inclusive of Electrical Control and Air Control Panels and Pipeline Air Boosters.

Without this Dense Phase conveying system, the sugar refinery would not be able to build the new processing facility on the other side of the plant 270m away with 8 pipe bends and receive the sugar in a cost-effective manner.

Icing Sugar Vacuum Conveying System

Filquip has specified, supplied and commissioned an Icing Sugar Vacuum Conveying System to transport 6TPH of Icing sugar a distance of 35m between the milled icing sugar storage hopper and the icing sugar packing machine storage bin.

The following equipment package was supplied by Filquip:

- 30kW Vacuum Blower System with Acoustic Enclosure.

- Drop Through Rotary Valve (Model RVS20.20, SS304, 1.1kW Motor).

- Six Borosilicate Glass Long Radius Bends (101.6mm OD, 500mm radius).

- Rotary Valve to Tube Venturi Transition Chute.

- Hepa Filter Intake Filter Box.

This Icing Sugar Vacuum Conveying System has been designed and supply to match the new Bauermeister Icing Sugar Mill installed onsite and the bag packing machines with flexibility in the conveying rate to balance the system.

Sugar Dust Extraction Systems

Filquip has specified, supplied and commissioned three Sugar Dust Extraction systems for a new refinery project.

The following equipment package was supplied by Filquip:

- White Sugar Dust Extraction – Polygonal FPHTXM22 Dust Collector.

- Icing Sugar Dust Extraction – Round FNXM4J16 Dust Collector.

- Waste Product Dust Extraction – Round FNS3J22 Dust Collector.

These three sugar dust extraction systems have been supplied with IECEX Componentry for all Dust Extractor parts that are inside the hazardous area zone.

Starch Bulk Bag Unloaders

Filquip has specified, supplied and commissioned a new Starch Bulk Bag Unloader with bag massaging system.

The following specifications were included for the Starch Bulk Bag Unloader:

- Forklift Loadable Bulk Bag Unloader Model SBB.125.

- Stainless Steel 304 Contact Parts, Painted Mild Steel Frame.

- 1.2m3 Hopper Capacity with Level Prove and Vent Outlet.

- Pneumatic Cylinder Massaging System.

This Starch Bulk Bag Unloader was built and supplied with IECEX electrical parts for all equipment located inside the hazardous area zone.

Clinker Dense Phase Conveying

Filquip has specified, supplied and commissioned a Clinker Dense Phase Conveying system to transport 3TPH of Abrasive Clinker Dust a distance of 140m from the grinding plant bag house dust collector to the process silos. This system allows the customer to recycle the clinker dust into the process:

The following equipment package was supplied by Filquip:

- Full Pipeline Dense Phase System for Clinker Dust 8TPA100FP Model.

- 283L Vessel Capacity, Throughput capacity of 3,000kg/hr at 140m distance.

- Inclusive of Electrical Control and Air Control Panels and Pipeline Air Boosters.

- Drop Through Rotary Valve (Model RV05.20, CS, 1.1kW Motor).

With the extreme abrasion of the clinker dust the Full Pipeline Clinker Dense Phase System provides a reliable solution with minimised maintenance requirements for the plant while retaining the dust and returning it to the process to reduce company costs.

Salt Dense Phase Conveying

Filquip has specified, supplied, installed and commissioned a skid mounted Salt Dense Phase Conveying system to transport 1TPH of Sodium Sulphate Salt from IBC containers to a receiver hopper.

The following equipment package was supplied by Filquip:

- 24L SS304 Dense Phase Conveyor

- PLC Dense Phase Control Panel Locally Mounted

- Forklift moveable SS304 Skid fabricated with local air receiver

- Compressed air filtration package for clean dry air on the skid

- Fabrication and installation of Site Receiver Hopper on load cells

- Site installation of conveying pipeline with camlock connection

The installation of this system has allowed the plant operators to load an IBC of product onto the Salt Dense Phase Conveying Skid and transfer it up into the plant weigh hopper on demand from the control room for each mix that required it, saving manual handling and labour from the previous hand pouring method.

Brewery Grain Vacuum Conveying System

Filquip has specified, supplied, installed and commissioned a grain storage and vacuum conveying system. The design transports 2.5TPH of malted barley brewery grain using a vacuum conveying system which draws the product from one of two storage silos and transports it 30m through a number of bends into the brewery mill.

The following equipment package was supplied and Installed by Filquip:

- 7.5kW Vacuum Blower System

- Three Drop Through Rotary Valve (Model RVR02.20, 0.55kW EXtD Motor)

- Two Borosilicate Sight Glasses (50.mm OD, 500mm long)

- Vacuum Receiver Separator Filter with Hopper & Explosion Panel (FNS3J22D)

- Receiver Load Cells for weighing product into the mill

- System control box and HMI for inputting the desired weight of grain to be vacuum conveyed and milled.

The installation of this system has allowed the brewery to buy their grain in bulk as opposed to the previous 25kg bags adding a considerable cost saving to the raw materials. The new system is also automated so plant operators are not manually handling the 25 kg bags of grain.

Coffee Bean Vacuum Loader

Filquip has designed, supplied and commissioned a Coffee Bean Vacuum Loader to transport Coffee Beans from 20kg and 70kg bags on the floor up into a coffee roaster or hopper. The system uses a suction wand which allows the staff to move the coffee beans without the risk physical injury through incorrect lifting techniques.

The following specifications were included for the Vacuum Loading System:

- Polished 304 Stainless Steel Construction.

- 2m Discharge Height with 3m Flexible Suction Hose with Wand.

- Mobile Conveying Unit on Lockable wheels.

- Single Start Button for automatic operation.

- 6 Models available up to 6m3/hr throughput.

- Available in 240V or Three Phase Power.

The implementation of this new coffee bean vacuum loading system has saved considerable time for the Coffee Roasters as they no longer need to carry the large bags of coffee beans from pallets up to the coffee roasting equipment.

Grain Loading Bellows

Filquip has specified, supplied and commissioned a new set of Grain Loading Bellows to fill/load open trucks with grain from bulk storage silos.

The following specifications were included for the Loading Bellows:

- 0.55kW IECEX Winch Motor.

- IECEX Junction Box and IECEX Level Indicators for Control Feedback.

- Inner and Outer Bellows system (No drop cones).

- Stroke of 3000mm (4830mm extended length, 1830mm retracted length).

- 440 m3/hr Throughput Capacity.

These loading bellows have been supplied with IECEX electrical parts for all equipment located inside the hazardous area zone.

Gypsum Silo Bin Activators

Filquip has specified and supplied a new set of two (2) Gypsum Silo Bin Activators and Isolation Slide Gate Valves for a Plaster Board Manufacturing Company.

The following specifications were included for the Bin Activators

- Model BA.1.1.2500.

- Painted Mild Steel Construction.

- Supplied with VLC.400 Circular Slide Gates on the Outlet.

- Fitted with Twin MVE1600/3 Electrical Vibrators.

- SINT polymer gasket material.

These Gypsum Silo Bin Activators were supplied directly to site in a high cube container to ensure transport damage was not incurred for such large diameter units.