Filquip has been providing Bin Activators for hopper and silo discharging systems for over 20 years for all types of powders and granular materials. We also supply Live Bin Bottom Screw Feeders for discharging particularly difficult materials from polygonal hoppers or silos.

The inverted cone which is a seamless construction in the EXTRAC Bin Activators serves three purposes:

- Imparts force into the product bulk to break potential arches.

- Reduces stresses in the Silo Outlet by shielding flow around and into the outlet.

- Providing a slot outlet and pseudo-plane flow, offering a favorable flow shape.

EXTRAC BA Bin Activators

EXTRAC BA Bin Activators

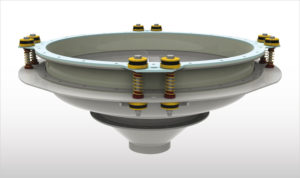

The EXTRAC BA Series of Bin Activators provide silo or bin discharging with controlled vibration through the product column for continuous extraction with optimal mass flow.

The BA Bin Activators consist of a seamless cone manufactured, a seamless SINT engineered polymer seal with integrated upper and lower flange, suspensions for connection with the silo cone, as well as one or two electric OLI motovibrators.

To fit the BA Bin Activator, the silo cone is shorter than usual, leaving a wide outlet section. A flange supplied before or together with the Bin Activator is welded on the silo outlet cone on site. Special suspensions and a seamless, flanged SINT engineered polymer seal form a flexible connection between silo and Bin Activator. One or two electric OLI motovibrators fitted on the unit generate vibration of the Bin Activator to facilitate a smooth material flow.

BA Bin Activators are used in various industrial applications to facilitate discharge of powdery or granular materials from a silo or hopper. The use of this equipment ensures optimum feeding of the material according to a “mass flow” condition, thus avoiding bridging or rat holing phenomena.

- Available in Stainless steel 304, Carbon steel or Carbon steel with food grade paint.

- Throughput range from 5m³/hr to 300 m³/hr.

- Diameters from 400 mm to 3000 mm.

- Standard gasket made from wear-resistant SINT engineering polymer.

- Optional gaskets available in Food grade FDA approved option and high temperature options.

- Wide range of baffle plates to suit the application and product being discharged.

- Seamless discharge cone & overall construction with 70% fewer welds than a traditional bin activator

- ATEX certified versions available.

- Negative Pressure build version available.

- Suspensions available that are suitable for installation on Aluminium Silos.

EXTRAC BAS Bin Activators

EXTRAC BAS Bin Activators

The EXTRAC BAS Bin Activators are silo or bin discharging devices that creates controlled vibration through the product column for continuous extraction.

The BAS Bin Activator consists of a half convex, half conical shape. Set in vibration it facilitates material flow from hoppers or silos. It consists of a seamless carbon or stainless steel cone, manufactured on a sheet metal lathe, a seamless SINT engineered polymer seal with integrated upper and lower flange, suspensions for connection of the Bin Activator with the silo, as well as one or two OLI electric motovibrators.

The BAS Bin Activator suits certain applications, especially in the flour milling industry, to facilitate discharging of powdery or granular materials from silos or hoppers. The use of this equipment ensures optimum feeding of the material causing a “mass flow” condition inside the silo, thus avoiding bridging or rat holing phenomena.

- Available in Stainless steel 304, Carbon steel or Carbon steel with food grade paint.

- Diameters from 600 mm to 2100 mm.

- Standard gasket made from wear-resistant SINT engineering polymer.

- Optional gaskets available in Food grade FDA approved option and high temperature options.

- Wide range of baffle plates to suit the application and product being discharged.

- Seamless discharge cone & overall construction with 70% fewer welds than a traditional bin activator

- ATEX certified versions available.

- Negative Pressure build version available.

- Suspensions available that are suitable for installation on Aluminium Silos.

EXTRAC BAF Bin Activators

EXTRAC BAF Bin Activators

The EXTRAC BAF Bin Activator is silo or bin discharging device specifically designed to meet the requirements of the Food Industry.

With its hygienic design and finishing, it complies with the food contact materials directive EC 1935/2004 and is suitable for a variety of applications in food processing.

The BAF Bin Activators are of a tapered conical shape that, due to vibration, facilitates material flow from hoppers or silos during discharge. Manufactured from stainless steel, the BAF Bin Activator offers a high quality smooth finished surface. The mating parts are continuously welded on both sides, deburred and smoothened on the edges, thus obtaining a perfectly smooth surface. As a result, material residue is reduced to the minimum.

- Available in Stainless steel 304L or Stainless Steel 316L.

- Throughput range from 5m³/hr to 320 m³/hr.

- Diameters from 400 mm to 3000 mm.

- Hygienic Design abscent of internal welding seams for minimum residue – zero contamination.

- Optional gaskets available in Food grade FDA approved option and high temperature options.

- Wide range of baffle plates to suit the application and product being discharged.

- Seamless discharge cone & overall construction with 70% fewer welds than a traditional bin activator.

- ATEX certified versions available.

- Negative Pressure build version available.

- Suspensions available that are suitable for installation on Aluminium Silos.

WAM Live Silo/Bin Bottoms MU

WAM Live Silo/Bin Bottoms MU

MU Live Bin Bottoms are the ideal solution for discharging particularly difficult materials from polygonal hoppers or silos.

MU Live Bin Bottom Feeders are used for extracting biological or industrial sludge, paper scrap, wood chippings, sawdust, flour, bran, chemical pellets and many other products. They are equipped with a modular trough which encloses up to 6 shafted helical flight or paddle screws, with fully protected end bearing assemblies complete with manually adjustable packing gland and shaft seal, a rectangular outlet spout covering the entire width of the bin bottom, bolted end plates, splined shaft couplings for medium duty, and flanged shaft couplings for the heavy-duty version.

MU Live Bin Bottoms are equipped with one gear motor per screw shaft or, depending on the application, with a drive unit driving more screws.

- Up to 6 shafted helicoid flight or paddle screws for product movement.

- Screw diameters from 150 to 600mm and trough length from 1,500 to 4,000mm.

- Available in Carbon steel or Stainless steel

Open MU Live Bin Bottom Screw Feeder Brochure