The experience of Filquip with lime dosing systems allows us to design packages that minimise the common lime problems associated with Blockages and Scale build up.

Lime Dosing System – Gibson Island WTP

Filquip was awarded the contract for the Design and Construction of the Lime Dosing System for the Gibson Island Water Treatment Plant.

The following equipment package was supplied, installed and commissioned:

- Two Lime Silos (125m3 Capacity Each).

- Lime Silo Bin Activators (One per Lime Silo).

- Two Microbatch Volumetric Feeders (MBF114 Model with Turndown Range 0.007 m3/min – 0.066 m3/min).

- Two Dosing Pumps (35 m3/hr each).

- Two Mixing Tanks (Stainless Steel 316, 12m3 volume each).

- Silo Pressure Relief Valves.

- Two Round FS4J39 Silo Dust Collectors (39m2 Cartridge Unit).

- Silo Load Cells and Weight Transmitter System.

- Silo Overfill Protection Systems.

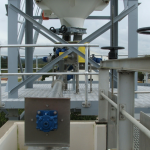

Lime Dosing Equipment – Bundamba WTP

Filquip was awarded the contract for the Design and Construction of the Lime Dosing System Lime Powder Handling at the Bundamba Water Treatment Plant.

The following equipment package was supplied, installed and commissioned:

- Two Lime Silos (72m3 Capacity Each).

- Lime Silo Bin Activators (One per Lime Silo).

- Two Microbatch Volumetric Feeders (MBF073A Model with Turndown Range 0.0018 m3/min – 0.015 m3/min).

- Silo Pressure Relief Valves.

- Two Round FS4J39 Silo Dust Collectors (39m2 Cartridge Unit).

- Silo Load Cells and Weight Transmitter System.

- Silo Overfill Protection Systems.

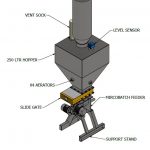

Mobile Lime Dosing System

Filquip has developed a Mobile Lime Dosing System of modular equipment for simple setup and operation. The Filquip Modular Lime Dosing System consists of the following key components:

- Telescopic Bulk Bag Unloading System with 304 Stainless Steel storage hopper.

- Slide gate valve for lime powder isolation.

- Bulk Bag Unloader Vibrators and Aerators for optimal Lime powder flow.

- TX Stainless Steel 304 Screw Conveyor 2.8m long at 45Deg incline.

- Dust Extraction System for Bulk Bag Unloading with integrated Rotary valve to return the dust into the Screw conveyor.

- Stainless Steel 304 Mixing Tank with 0.55kW Mixer, Access Hatches, Level Sensor and Lime Slurry Outlet Process Connections.

Filquip lime dosing systems are also available on a forkliftable skid frame with integrated control panel for a fully Mobile Lime Dosing Solution.

Lime Vacuum Loader

Filquip has designed, supplied and commissioned a Lime Vacuum Loader and dosing system to convey bags of Lime into a day hopper with a Volumetric Screw Feeder to dose the lime into the plant process. The system uses a suction wand which allows the staff to vacuum loader the powders without the risk physical injury through incorrect lifting techniques.

The following Filquip equipment package was provided for the Lime Vacuum Loader:

- Polished 304 Stainless Steel Construction for the FVC-1 Vacuum Loader

- 100L Stainless Steel 304 Day Hopper with aeration and a level probe

- Single Start Button for automatic operation.

- 750L/hr vacuum loader capacity

- MBF042 Microbatch Feeder for dosing the lime (MBF042A 0.3L/min – 1.3L/min)

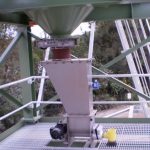

Hydrated Lime Dosing System – Maroochy WTP

Filquip has specified, supplied, installed and commissioned a Hydrated Lime Dosing System for Maroochy WTP in Queensland, Australia.

The following Filquip equipment package was provided for this Hydrated Lime Dosing System:

- One (1) 70m3 Lime Silo in Painted Mild Steel with Silo overfill Protection System and Instrumentation .

- One (1) 1800mm diameter silo bin activator.

- Two (2) TX100.4700 Screw Conveyors, 100mm diameter, 4.7m long in Stainless Steel 304.

- Two (2) MBF073N Microbatch Volumetric Screw Feeders with a 1.8 to 15 L/Min Volumetric Dosing Rate.

- One (1) FS3J24 Round Dust Extractor Unit.

Hydrated Lime Dosing System – Murrumba Downs WWTP

Filquip was awarded the contract for the Design and Construction of the Hydrated Lime Dosing System at the Murrumba Downs Waste Water Treatment Plant.

The following equipment package was supplied, installed and commissioned:

- Two Hydrated Lime Silos (20m3 Capacity Each).

- Hydrated Lime Silo Bin Activators (One per Lime Silo).

- Two Microbatch Volumetric Feeders (MBF042A Model with Turndown Range 0.0003 m3/min – 0.0013 m3/min).

- Silo Pressure Relief Valves.

- Two Round FS4J24 Silo Dust Extrractors (24m2 Cartridge Unit).

- Silo Load Cells and Weight Transmitter System.

- Silo Overfill Protection Systems.