Filquip has been providing hopper and silo discharging systems for over 20 years for all types of powders and granular materials with one of the simplest methods by using Air Slides and Air Slide Material.

Air Slide Material

Air Slide Material

Filquip works in partnership with leading airslide conveying fabric manufacturers to offer a comprehensive range of Air Slides and Air Slide Material.

We supply Air Slide Material for powder conveying to the bulk materials handling industry to standard dimensions or custom dimensions as required. Filquip only supplies Air Slide Material and Air Slide Matting that has even air permeability with weaving for minimizing abrasion.

We generally carry the following roll widths as stock off the shelf to cut your desired length:

- 305mm wide

- 350mm wide

- 380mm wide

- 415mm wide

- 450mm wide

- 500mm wide

- 1600x1600mm squares (to cut silo base profiles from or any other shape required)

- 1600mm wide rolls x 10m long each in individual crates

We can supply different airslide materials for temperatures as low as -60 Deg C up to maximum temperatures of 250 Deg C with short periods up to 450 Deg C.

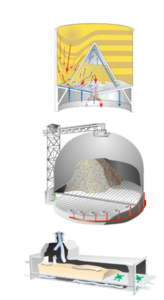

Our Air Slide Mats are used in:

- Pneumatic Loading Systems.

- Pneumatic Discharge Systems.

- Air Slides.

- Storage Silos.

- Fluidising basins.

- Railway Wagons Discharging Cones.

- Tanker Trucks.

- Isotainers.

- Powder Coating Machine Sinter Basin Bottoms.

- Powder Containers and many other applications.

Open Air Slides and Air Slide Matting Brochure

Air Slides

Air Slides

Filquip is provider of new Air slide systems (Also know and air gravity conveyors) to the bulk materials handling industry to meet the custom dimensions for your project.

Air Slides use pressurised air and gravity to move powder products without any moving parts making them ideal for discharging cements and other abrasive building products from Silos and Hoppers with a slight decline angle as low as 1.5 degrees.

The compressed air enters the bottom chamber through inlet ports which then permeates through the Air Slide Matting and fluidises the product conveying it to the outlet.

- Low energy requirements due to the small volume of air required to move high capacities.

- Extremely low operating noise level.

- Installed overhead to save floor space.

- Minimal maintenance as there are no moving parts.

- Dust tight casing construction resulting in an environmentally friendly option.

- No lubrication required