Filquip offers a range of sizes for Submersible Chopper Pumps by Speco/Sepcom. The WSP type pumps are also known as submersible macerator pumps and are typically used in slurry processing, livestock waste, biogas and civil/industrial effluent processing plants.

VPH Vertical Long Shaft Submersible chopper pumps

VPH Vertical Long Shaft Submersible chopper pumps

The VPH Vertical Submersible Chopper pumps allow high pumping capacity and cutting effiency . They are designed to pump slurry liquids containing solid lumps or fibres including sewage, waste water and livestock waste.

The effluent materials are chopped up both by the screw and by the built-in cast-iron or stainless-steel chopper installed in the pump housing. The shredded material is conveyed out of the tank or pit through the delivery pipe made of stainless steel too.

- Throughput rates available up to 69 L/s (250 m³ / hr).

- Pumping up to a maximum head of 24m.

- Drive power options from 7.5kW to 22kW depending on throughput requirements.

- Suitable for tanks and pits to 5.5m depth

- Wide range of mounting options and accessories available.

Open VPH Vertical Submersible Chopper Pumps Brochure

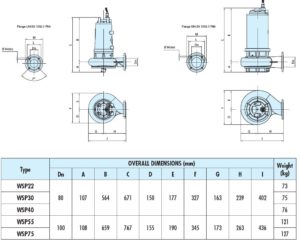

WSP Submersible chopper pumps

WSP Submersible chopper pumps

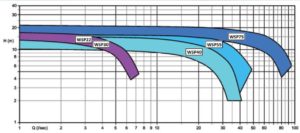

The WSP Submersible Chopper pumps are designed to pump slurry liquids containing solid lumps or fibres including sewage, waste water, livestock waste, biogas digestate and civil/industrial effluents.

The units consists of a waterproof outer steel shell for direct immersion in the slurry/liquid waste. The motor is a waterproof build and the hardened cast iron chopper blade is specifically designed for sewage, slurry processing, livestock waste, biogas digestate and civil/industrial effluent.

- Throughput rates available up to 90 L/s (324 m³ / hr).

- Pumping up to a maximum head of 21.5m.

- Drive power options from 2.2kW to 7.5kW depending on throughput requirements.

- Outlet sizes in DN80 and DN100mm.

- Vertical or Horizontal mounting options.

- High performance mechanical seals are included as standard along with a leakage sensor.

- Economical purchase price.

- Low running costs and simple maintenance.

- Wide range of mounting options and accessories available.

Open WSP Submersible Chopper Pumps Brochure

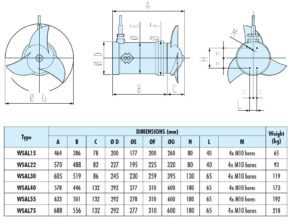

WSA Submersible Agitators and Mixers

WSA Submersible Agitators and Mixers

The WSA type submersible agitators are designed to keep medium and low density liquid suspensions blended in tanks, pits or chambers.

The units consists of a coated cast iron motor casing with water proof enclosure for direct immersion in the slurry. The motor is a waterproof build and the Stainless Steel propeller is specifically designed for slurry processing, livestock waste, biogas and civil/industrial effluent.

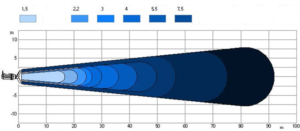

- Provides efficient mixing and blending up to 40m.

- Drive power options from 1.5kW to 7.5kW depending on tank/pit size agitation requirements.

- High performance mechanical seals are included as standard along with a leakage sensor.

- Economical purchase price.

- Low running costs and simple maintenance.

- Wide range of mounting options and accessories available.

Open WSA Submersible Agitators and Mixers Brochure

The power size of the agitator is generally calculated based on the volume of the tank/pit and the type of slurry mix that we wish to keep in suspension.

- Civil Slurries = 40 W/m³

- High Fibre Content Waste = 80 W/m³

- High Sand Content Waste = 200 W/m³

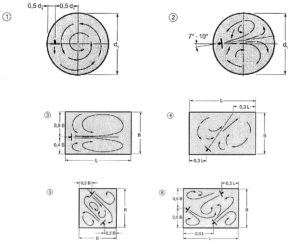

An essential advantage of a horizontally operating submersible mixers compared to conventional mixers is its ability to operate in different directions. Allowing the currents required in proportion to the slurry mix composition can be optimised.

- A circular rotating current the the simplest type to keep a mix with a high percentage of solids in suspension as a relatively high current speed can be achieved in a short operating time (Some heavier particles can settle in the centre of the tank).

- Using an angle of 7 – 10 degrees an efficient round tank mixing pattern can be achieved when the height

of the fluid in the tank is within the ratio of 0.3 to 1 times the diameter of the tank. - Rectangular and Square Tanks can be mixed in a length ways manner if the width of the tank is less than 5 to 8 times the diameter of the mixer propeller.

- For larger rectangular/square tanks a cross flow current is preferred.

- If the size of the tank if very large then several mixers are recommended to be utilised.