Container Unloading Screw Conveyor

Filquip has supplied, installed and commissioned a Container Unloading and Transfer System for Unloading Containers of PVC powders and conveying it into Storage Silos. The system has been sized to fully decant a container of PVC powder in 45 minutes using a Stainless Steel Screw Conveyor to decant the container into the Surge Hopper. A second stainless steel calcium carbonate screw conveyor was supplied to feed into the system.

The following equipment package was supplied:

- Container Unloading Chute and TX250.6000 Stainless Steel PVC Resin Screw Conveyor.

- Bulk Bag Unloader TX200.4500 Stainless Steel Calcium Carbonate Screw Conveyor.

- 2.2m3 Stainless Steel Intermediate hopper.

- Stainless Steel Dense Phase Transfer System (12TPA500).

- Bulk Bag Unloader system for additional feed from bulk bags into the storage silos.

Cement Batch Plant Screw Conveyors

Filquip has designed, supplied and commissioned a set of four (4) ES273 Screw Conveyors 8m long each for conveying Cement and Fly ash from Silos in a Low profile Batch Plant.

The following equipment package was supplied:

- Four (4) ES273.8000 Screw Conveyors, 250mm diameter, 8m long in Painted Mild Steel.

- Silo aeration airslide media.

- Silo plan air slides media.

The use of Screw Conveyors for transfer of the batch plant products from each silo into the weigh bins reduces the overall height of the batch plant to become a “low profile” concrete batch plant.

Flyash Screw Conveyors

Filquip has designed, supplied and commissioned a set of three piggy back screw conveyors for transferring FlyAsh to a loading bellow for Outloading from the power plant into tank trucks.

The following equipment package was supplied:

- Three (43) TC323.5800 Screw Conveyors, 300mm diameter, 5.8m long in Painted Mild Steel.

- ZAMBA Bellowjet Loading Bellows with integrated dust extractor.

- Mobile Fabricated Frames for Screw Conveyors and Loading Bellows.

The use of this mobile screw conveyor setup allows the extraction of the flyash from under the Power Plant storage hoppers and efficient dust free loading of this fly ash into tanker trucks.

Hazardous Area Starch Screw Conveyors

Filquip was awarded the contract for the Design and Construction of a Starch Handling System which includes inclined, horizontal and vertical hazardous area starch screw conveyors.

The following equipment package was supplied:

- Inclined ES273.4500 Screw Conveyor 250mm diameter, 4.5m long in Painted Mild Steel.

- Horizontal ES219.1500 Screw Conveyor 200mm diameter, 1.5m long in Painted Mild Steel.

- Vertical ES273.4500 Screw Conveyor 250mm diameter, 4.5m long in Painted Mild Steel.

- Starch Storage Silo (70m³ Capacity, Painted Mild Steel).

- Silotop Silo Dust Vent.

- Silo Explosion Panels.

- Silo Overfill Protection System (PRV, Control Panel, Level Sensor, Vibrator, Valves).

- Two Bulk Bag Unloaders (Model SBB.125, Painted Mild Steel).

Stone Dust Screw Conveyors

Filquip has supplied an Asphalt plant Stone Dust Conditioning system used to load open trucks with the excess stone dust generated by the plant without the requirement for closed tanker trucks or vacuum trucks for removal. The Stone Dust is conveyed by the Screw Conveyor from the Silo out to a point where the truck can be effectively filled.

The following equipment package was supplied by Filquip:

- TC273.6000 Screw Conveyor, 250mm diameter, 6m long in Painted Mild Steel.

- Dustfix Dust Conditioner (Dustfix 40 Model, 40m3/hr capacity).

The use of this system has saved the Asphalt Plant operator $60,000 over the first 3 months of operation from the reduced costs of needing specialist subcontractors to remove the stone dust, the use of open top trucks is a much more cost-effective solution made possible by this Stone Dust Conditioning System.

Shaftless Sludge Screw Conveyors

Filquip has designed, supplied and commissioned a set of Two reversible shaftless sludge screw conveyors to the Northpine WTP. These Sludge Screw Conveyors transfer the sludge from the Centrifuges to 3 possible outlets to fill portable bins below.

The following equipment package was supplied by Filquip:

- Two Reversible Stainless Steel Screw Conveyors (Model SSC, 300mm diameter, SS304, 4580mm Long, 3kW Motor).

- Two Pneumatic Slide Gates for middle screw conveyor outlet.

- Six Drop Chutes from outlets to transport sludge skips.

The modular nature of the SSC Screw Conveyor Manufacturing Process ensures that standardised spare parts are available for these shaftless sludge screw conveyors as opposed to custom built units which may not use standardised modular parts.

Quarry Stone Dust Screw Conveyors

Filquip has specified, supplied, installed and commissioned a set of Quarry Stone Dust Screw Conveyors.

- One (1) ES273.4000 Inclined Screw Conveyor, 250mm diameter, 4m long in Painted Mild Steel with Hardened Face Flight.

- One (1) ES219.3000 Inclined Screw Conveyor, 200mm diameter, 3m long in Painted Mild Steel with Hardened Face Flight.

- One (1) CAU219.1200 Horizontal Trough Screw Conveyor, 200mm diameter, 1.2m long in Painted Mild Steel with Hardened Face Flight.

- One (1) Double Dump Valve

- One (1) Transition Hopper with U060 Aerators

Cement and Aggregates Screw Conveyors

Filquip has specified and supplied two Heavy Duty Trough Screw Conveyors to handle the building materials Cement, Flyash, Sand and Aggregates up to 16mm in size for a new Bagging Line.

Filquip supplied WAM Screw Conveyors with the model build code CAU1E.SAC.250 to the following specifications:

- Painted Mild Steel 275mm Trough Construction, sized for the large aggregate stones to avoid binding or pegging of the auger.

- Mild Steel 200mm Diameter Auger with triple hard facing for wear resistance.

- SAC Screw Conveyor for heavy duty operation with 114mm Centre Pipe for the Auger.

Calcium Carbonate and Sand Screw Conveyors

Filquip has specified, supplied, installed and commissioned a set of Six Calcium Carbonate and Sand Screw Conveyors for a Cementatious Materials Mixing Plant. These Screw Conveyors transfer the products from each Hopper, Silo or Bulk Bag Unloader to a Surge hopper which then allows them all to be Dense Phase Conveyor into the mixing room within the plant.

The following Filquip equipment package was provided for these Calcium Carbonate and Sand Screw Conveyors:

- Two (2) ES323.5000 Inclined Screw Conveyors, 300mm diameter, 5m long in Painted Mild Steel.

- Two (2) ES323.6500 Inclined Screw Conveyors, 300mm diameter, 6.5m long in Painted Mild Steel.

- One (1) AT273.1200 Horizontal Screw Conveyor, 250mm diameter, 1.2m long in Painted Mild Steel.

- One (1) VE273.4000 Vertical Screw Conveyor, 250mm diameter, 4m long in Painted Mild Steel.

- One (1) SBB.125 Bulk Bag Unloader

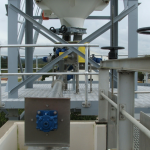

PAC Screw Conveyor

Filquip has specified, supplied, installed and commissioned a Powder Activated Carbon Dosing System in Queensland, Australia including a PAC Screw Conveyor.

The following Filquip equipment package was provided for this PAC Dosing System:

- One (1) AT219.2000 Horizontal Screw Conveyor, 200mm diameter, 2m long in Painted Carbon Steel.

- One (1) VE219.6500 Vertical Screw Conveyor, 200mm diameter, 6.5m long in Painted Carbon Steel.

- One (1) MBF073A Microbatch Volumetric Screw Feeder with a 1.8 to 15 L/Min Volumetric Dosing Rate.

- One (1) SBB.125 Bulk Bag Unloader.

- One (1) 15m3 Bulk Storage Silo with Silo Overfill Protection System

Hydrated Lime Stainless Steel Screw Conveyors

Filquip has specified, supplied, installed and commissioned a Hydrated Lime Dosing System in Queensland, Australia including a Hydrated Lime Stainless Steel Screw Conveyor.

The following Filquip equipment package was provided for this Hydrated Lime Dosing System:

- Two (2) TX100.4700 Screw Conveyors, 100mm diameter, 4.7m long in Stainless Steel 304.

- Two (2) MBF073N Microbatch Volumetric Screw Feeders with a 1.8 to 15 L/Min Volumetric Dosing Rate.

- One (1) 70m3 Bulk Storage Silo with Silo Overfill Protection System.

- One (1) 1800mm diameter bin activator

- One (1) FS3J24 Dust Extractor Unit.

Zeolite Stainless Steel Screw Conveyors

Filquip has specified, supplied, installed and commissioned a Zeolite Dosing System in Queensland, Australia including a Zeolite Stainless Steel Screw Conveyor.

The following Filquip equipment package was provided for this Zeolite Dosing System:

- One (1) TX300.6000 Inclined Screw Conveyor, 300mm diameter, 6m long in Stainless Steel 304.

- One (1) Stainless Steel 304 Intermediate Hopper with Breather Sock and Flow Aids.

- One (1) MBF073A Microbatch Volumetric Screw Feeder with a 1.8 to 15 L/Min Volumetric Dosing Rate.

- One (1) 15m3 Bulk Storage Silo with Silo Overfill Protection System