Filquip is a provider of Potable Water & Sewage Treatment Equipment. Filquip supplies WAM and Savi technologies and are leaders in primary water treatment (Inlet Works) equipment including screens, grit separation, compactors and chemical dosing systems. Filquip is a provider of dosing systems including Lime, Polymer, PAC, DOT, Zeolite and many other products.

Open Water and Sewage Treatment Equipment Brochure

WAM Chemical Dosing Microbatch Feeders MBF

WAM Chemical Dosing Microbatch Feeders MBF

The WAM MBF range of micro-batch feeders (volumetric feeder) provide accurate volumetric feeding of powder and granular materials.

- Stainless steel body, Agitator tool and Feeder screw.

- Available with Horizontal or Vertical spout outlets.

- Available with food-grade and ATEX zone versions.

- Throughputs of up to 6m³ / hr.

- Integration with a loss in weight system or VSD can provide automated accurate batching systems.

Open Microbatch Feeders Brochure

SAVI Band Screens & Bar Screens GV Series

SAVI Band Screens & Bar Screens GV Series

Filquip supplies a range of Savi Band and Bar Screens for Municipal and Industrial Waste Water Treatment of study construction capable of handling hard materials in the flow stream.

- Coarse Mechanical Bar Screens (GVB model) are available for channel widths from 400 to 2000mm with bar spacing from 12 to 50mm. Chain driven rakes clean the bars.

- Fine Mechanical Bar Screens (GVF model) are available for channel widths from 400 to 2000mm with bar spacing from 6 to 10mm. Chain driven rakes clean the bars.

- Fine Perforated Screens (GVS model) are available for channel widths from 400 to 2000mm with 3 to 6 mm perforation options. Brushes and Wiper Blades clean the screen.

- Available in Galvanised Steel, Stainless Steel 304 & 316

Open Fine Bar Screens Brochure

Open Perforated Screens Brochure

SAVI Belt Screen VFR

SAVI Belt Screen VFR

The Savi VFR Belt Screen is used for in-channel fine screening of waste water. Utilising filtering steps of perforated plate to screen solids along the belt to the top outlet of the screen.

- Channel widths from 750 to 2,250mm with 3 to 7mm perforation options.

- Available in Galvanised Steel, Stainless Steel 304 & 316.

- Double cleaning system of a motorised roller brush and a washing bar.

SAVI Step Screens VTR

SAVI Step Screens VTR

The Savi VTR Step screen is designed for in-channel fine screening of waste water. It consists of two sets of lamellae one moving and one fixed to step the waste up the screen to the outlet.

- Available in channel widths from 560 to 1800mm wide with 3 to 6mm filter spacing.

- Available in Stainless Steel 304 and 316.

SAVI Rotating Drum Screens VSA/Spiramatic

SAVI Rotating Drum Screens VSA/Spiramatic

Filquip offers a range of Savi rotating drum screens including Pre-MBR screens in its Spiramatic series.

- VSA Fine Drum Screens are available for channel widths from 600 to 3000mm with wedge wire, perforated plate or mesh media openings from 0.5 to 10mm.

- VSA Pre-MBR Fine Drum Screens are available for channel widths from 600 to 3000mm with perforated plate openings in 1, 1.5, 2 and 3mm sizes, with a triple face seal.

- Systems can be channel mounted or tank mounted and have optional sliding aluminium or stainless steel covers.

SAVI Rotary Screens

SAVI Rotary Screens

Filquip offers a range of Savi internally and externally fed rotary screens for industrial and municipal waste water treatment.

- RTV Internally Fed Rotary Screens with media screening from 1 to 6mm. Designed for connection to pipework for screening liquid flows to up 360L/S.

- SGR Externally Fed Rotary Screens with media screening from 1 to 6mm. Non-channel flow applications for screening liquid to up 580L/S. Available with and without overflow.

- Systems are both self-cleaning with spray nozzles.

SAVI Screw Compactor / Screenings Compactor VWP

SAVI Screw Compactor / Screenings Compactor VWP

Filquip offers a range of Savi VWP screw compactors and screenings washer compactors for industrial and municipal waste water treatment.

- The screw washer compactor can reduce screenings by up to 65% of their volume at a flow rate up to 6m³/hr.

- Available in Stainless Steel 304 and 316.

- Bagger option available.

Open Shafted Washer Compactors Savi-VWP Brochure

Open Shafted Washer Compactors Savi-VWP-WM Brochure

SPECO Screw Screens

SPECO Screw Screens

Filquip offers a range of Speco screw screens for in-channel, in-tank or connecting pipework applications.

- The GCP in-channel screw screen provides solids extraction from the waste water stream at a flow rate up to 270 L/S in channel sizes between 300 to 850mm.

- The GCPC pipework flow screw screen provides solids extraction from the waste water stream at a flow rate up to 270 L/S with Inlet pipe sizes between 200 – 350mm diameter.

- Available in Stainless Steel 304 and 316.

SPECO Combined Mechanical Pre-Treatment Screening Systems

SPECO Combined Mechanical Pre-Treatment Screening Systems

The Speco Wastemaster series of mechanical pre-treatment systems utilise their own self-supporting tank to extract solids from the waste stream and compact these for disposal or reuse. The Wastemaster series is ideal for septage receival stations or pre-septic tank operations.

The Wastemaster TSF1/TSB1 consists of a Screen, Solids conveying screw and Compactor and can handle flow rates up to 30 L/S.

The Wastemaster TSF1/TSB1 consists of a Screen, Solids conveying screw and Compactor and can handle flow rates up to 30 L/S.- The Wastemaster TSF2/TSB2 consists of a Screen, Solids conveyor screw, Compactor and Sand Separator and can handle flow rates up to 30L/s.

- The Wastemaster TSF3/TSB3 consists of a Screen, Solids conveyor screw, Compactor, Sand separator and Grease remover and can handle flow rates up to 210L/s with solids percentages greater than 15%.

- Available in Stainless Steel 304 or 316

Open TSF1 Wastemaster Brochure

Open TSF2/3 Wastemaster Brochure

SAVI Grit Classifiers & Sand Washers CLS

SAVI Grit Classifiers & Sand Washers CLS

The Savi CLS and CLSW series of Grit classifiers and Sand washers separate sand and grit contained in waste water and then wash it to reduce the quantity of organic particles.

- Available in 3 sizes with flow rates up to 30L/s.

- 97% organic separation efficiency.

- Available in Stainless Steel 304 or 316

Open Sand & Grit Washers Savi-CLSW Brochure

SPECO Grit Separators DS

SPECO Grit Separators DS

The Grit Separator controls the flow of the waste water to allow sedimentation of the sand and grit from the stream. The outloading screw conveyor then discharges the grit through the upper outlet.

- Flow rates up to 10L/s.

- Solids through put up to 1.29 m³ / hour.

- Available in the Fluid Dynamic Model for sand and grit separation down to 200 micron.

- Available in Stainless Steel 304 or 316.

RONCUZZI Screw Pumps PA

RONCUZZI Screw Pumps PA

The RONCUZZI PA series of Archimedean Screw Pumps provide a cost-effective solution for pumping water with constant efficiency even when there are changes in the flow rate.

- Can be used in contaminated water containing solids.

- Low wearing due to the slow speeds of operation.

- Flow rates up to 4,305 L/S Available.

Open PA Archemedian Water Screw Pump Brochure

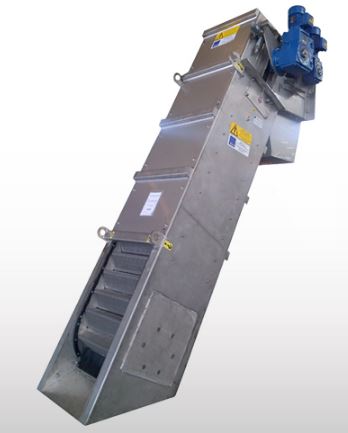

WAM Shaftless Screw Conveyors TU

WAM Shaftless Screw Conveyors TU

Filquip supplies a large range of WAM trough shaftless screw conveyors for handling sludge and screenings.

The WAM SSC Shaftless Spiral screw conveyors is built to convey difficult materials. Available in multiple configurations including high temperature options. They are designed for handling of urban solid waste, screenings and floating matter, dewatered, thickened, or conditioned sludge, packaged food, creams or pastes, as well as waste from meat, fish, fruit and vegetable processing.

Material is conveyed by an extra heavy-duty shaftless screw spiral that slides on a wear-resistant, low-friction liner inside the conveyor trough housing. The longitudinally divided U-section troughs are manufactured from carbon or 304 L / 316 L stainless steel, including an appropriate surface treatment.

- Trough and spiral manufactured from carbon steel or 304L / 316L stainless steel and includes UHMWPE trough liner

- Trough screw diameters of 150, 200, 250, 300, 350, 400, 500 and 600mm.

- Numerous inlet and outlet options including spigot, round and square flanges and universal.

- Standard or custom built screw conveyors including options for multiple inlets and outlets, liners and wear bars, reversible operation and with inspection hatches as required.

- Throughputs of up to 45m³ / hr for sludge and 13m³ / hr for screenings.

Open SSC Shaftless Spiral Conveyor Brochure

EXTRAC Bulk Bag Unloader SBB

EXTRAC Bulk Bag Unloader SBB

The SBB Bulk Bag unloader provides an effective solution to unloading bulk bags of product in an efficient manner.

- Available in a half frame height where a crane or forklift is utilised to lift and hold the bag during unloading.

- Available in full frame height with telescopic rails for bag loading into the frame.

- Includes a vibrating pan plate and dust collection point to ensure efficient and clean bulk bag unloading.

- Bulk Bag Unloaders are available in Carbon steel, Stainless steel 304 and Stainless steel 316.