Filquip has been supplying WAM Screw Conveyors also known as Augers since 1999 to the materials handling industry with Tubular and Trough options. Filquip has also supplied the water water treatment industry with Shaftless Sludge conveyors.

WAM Screw Conveyors – Tubular

WAM Screw Conveyors – Tubular

Filquip offers the WAM ES screw conveyor as the quintessential method of powder and granule feeding and conveying. In over 4 decades over 500 million ES series Screw Conveyors have been sold around the world.

The ES and more specialised TU Screw Conveyor Systems are manufactured from carbon steel with suitable surface finishing and powder coating. They are made up from a tubular trough equipped with at least one inlet and outlet spout, a welded flange at each tube end, helicoid screw flighting welded on a centre pipe with coupling bush at each end, two end bearing assemblies complete with self-adjusting shaft seal (one of the bearing assemblies is integrated into the drive unit), and a number of intermediate hanger bearings depending on the overall length.

- Tubular screw diameters of 114, 139, 168, 193, 219, 273, 323, 406, 457, 558 & 600mm.

- Numerous inlet and outlet options including spigot, round and square flanges and universal.

- Standard or Custom built screw conveyors including options for multiple inlets and outlets, reversible operation and with inspection hatches as required.

- Option for “Universal Inlet/Outlet” for simple installation to a site fit angle.

Open Tubular Screw Conveyors Brochure

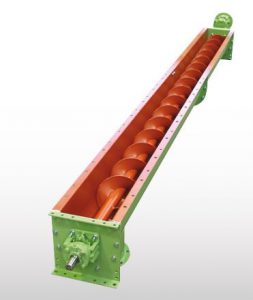

WAM Screw Conveyors – Trough

WAM Screw Conveyors – Trough

Filquip offers the WAM modular CA Trough Screw Conveyor system as a highly versatile solution for conveying powdery or granular materials. They are widely used all over the world in industries such as pet food, plastics processing, soap, washing powder and detergent processing, animal feed milling, wood processing, chemicals, environmental technology, cement, lime and gypsum processing, as well as mining. Depending on the material to be handled, CA Trough Screw Conveyors come in a light, medium-heavy, or extra heavy-duty design. All types are available with Hazardous Area Zone 22 certification.

The CA Screw Conveyor has a U or V-shaped trough equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with coupling bush at each end, two end bearing assemblies complete with shaft seal, a certain number of intermediate hanger bearings depending on the overall length of the screw conveyor, and bolted trough cover sections.

- Trough screw diameters of 150, 200, 250, 300, 350, 400, 500 and 600mm.

- Numerous inlet and outlet options including spigot, round and square flanges and universal.

- Standard or custom built screw conveyors including options for multiple inlets and outlets, liners and wear bars, reversible operation and with inspection hatches as required.

- Shaft or Shaftless options available for flights.

- Throughputs of up to 100m³ / hr.

Open Trough Screw Conveyors Brochure

WAM Shaftless Screw Conveyors SSC

WAM Shaftless Screw Conveyors SSC

Filquip supplies a large range of WAM trough shaftless screw conveyors for handling sludge and screenings.

The WAM SSC Shaftless Spiral screw conveyors is built to convey difficult materials. Available in multiple configurations including high temperature options. They are designed for handling of urban solid waste, screenings and floating matter, dewatered, thickened, or conditioned sludge, packaged food, creams or pastes, as well as waste from meat, fish, fruit and vegetable processing.

Material is conveyed by an extra heavy-duty shaftless screw spiral that slides on a wear-resistant, low-friction liner inside the conveyor trough housing. The longitudinally divided U-section troughs are manufactured from carbon or 304 L / 316 L stainless steel, including an appropriate surface treatment.

- Trough and spiral manufactured from carbon steel or 304L / 316L stainless steel and includes UHMWPE trough liner

- Trough screw diameters of 150, 200, 250, 300, 350, 400, 500 and 600mm.

- Numerous inlet and outlet options including spigot, round and square flanges and universal.

- Standard or custom built screw conveyors including options for multiple inlets and outlets, liners and wear bars, reversible operation and with inspection hatches as required.

- Throughputs of up to 45m³ / hr for sludge and 13m³ / hr for screenings.

Open SSC Shaftless Spiral Conveyor Brochure

WAM VE-AT Horizontal – Vertical Screw Conveyors

WAM VE-AT Horizontal – Vertical Screw Conveyors

The VE-AT Horizontal and Vertical Screw Conveyor range provide an efficient conveying method with minimal footprint.

The Horizontal Screw Conveyor consists of a tubular or trough conveyor section with screw flighting selected for the powder or granule material being handled. The of the horizontal screw feeder consists of a short tubular section flanged to feed into the Vertical Screw Conveyor.

The Vertical Screw Conveyor consists of a tubular housing complete with the above-mentioned inlet in the bottom section. The Vertical Screw Conveyor has a top-mounted drive unit with integrated end bearing assembly (from which the screw is suspended) and self-adjusting shaft seal is specific for the application.

- Diameters of 114, 139, 168, 193, 219, 273 and 323mm.

- Elevation height in 1m steps from 1m to 20m tall.

- Throughput rates from 3m3/hr to 95 m3/hr available.

- Available in High Temperature service version.

- Horizontal screw conveyors with an inlet options to suit any chute, bulk bag unloader, bag feeder, silo or hopper.

- Eight outlet position options for the Vertical Screw Conveyor.

- Standard or Custom-built screw conveyors including options for multiple inlets and outlets, reversible operation and with inspection hatches as required.

- Small Footprint – Smaller dimensions compared with Bucket Elevators.