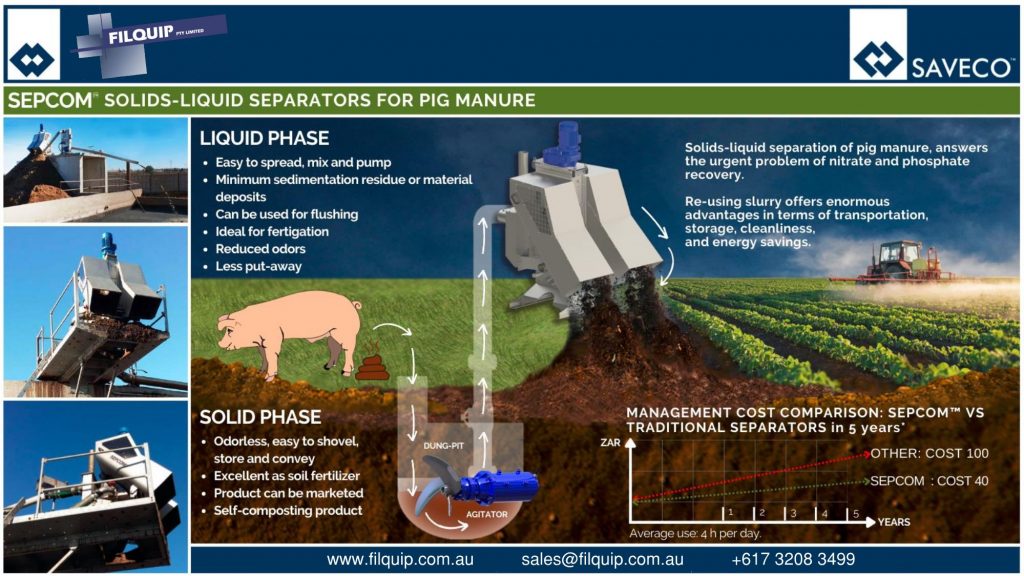

Filquip offers a range of Solids-Liquids Seperators for Animal Waste Dewatering and Compaction including the SEPCOM unit specifically designed to dewatering animal manure and Biogas digestate.

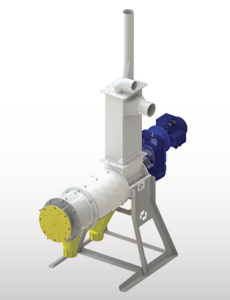

Vertical Animal Liquid Seperator SEPCOM

Vertical Animal Liquid Seperator SEPCOM

The Vertical Biogas Liquid Seperator SEPCOM unit is specifically designed for dewatering Biogas plants producing irregular shaped digestate low in fibre.

The special design of the machine ensures there is no clogging and no loss of the solids plug during operation. The Vertical Biogas Liquid Seperator SEPCOM performins separation by both gravity and mechanical compression, the machine is designed to separate the liquid phase from the solid phase of a wide range of materials such as sludge, sewage, manure, vegetable and fruit processing waste and, in general, solids-liquid mixtures in which the percentage of liquid inside the solids may differ considerably. The separated solid phase and liquid phase can both be easily and cheaply handled.

- Up to 28% dry matter.

- Never loses its solid plug.

- Includes a balance tank for stable feeding.

- The special shape of the screen chamber facilitates self cleaning.

- Available in 3 sizes: DN150 for 20m3/hr throughput , DN200 for 45 m3/hr throughtput and DN250 for up to 65 m3/hr throughput.

- Available in screen sizes down to 250 microns.

- The vertical Biogas Liquid Seperator SEPCOM has a small footprint for simple integration into an existing facility.

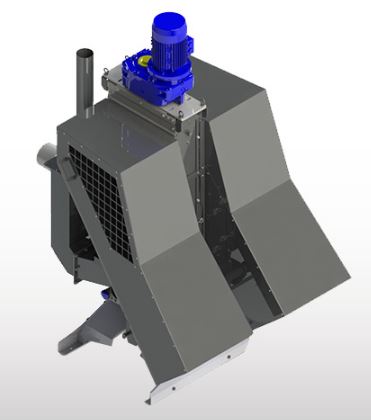

Horizontal Animal Liquid Seperator SEPCOM

Horizontal Animal Liquid Seperator SEPCOM

The Horizontal Biogas Liquid Seperator SEPCOM unit is ideal for dewatering fibrous Biogas digestate such as that from corn silage and cow manure.

The Horizontal Biogas Liquid Seperator SEPCOM performs separation by both gravity and mechanical compression, the machine is designed to separate the liquid phase from the solid phase of a wide range of materials such as sludge, sewage, manure, vegetable and fruit processing waste and, in general, solids-liquid mixtures in which the percentage of liquid inside the solids may differ considerably. The separated solid phase and liquid phase can both be easily and cheaply handled.

- Up to 30% Separated solids.

- Self adjusting solids outlet pressure for safe continuous operation.

- Available in 3 sizes: DN150 for 20m3/hr throughput , DN260 for 45 m3/hr throughtput and DN260L for up to 65 m3/hr throughput.

- Available in screen sizes down to 250 microns.

Biogas Solids-Liquids Seperator SPECO Microfilter MFT

Biogas Solids-Liquids Seperator SPECO Microfilter MFT

The MFT Microfilter is designed to be integrated into a filtration system to allow filtration of the liquid phase down to a micro level.

The unit consists of a micro-filtering system used for pretreatment upstream of the centrifuge or for some processes as an alternative system to the centrifuge.

The micro-screened liquid can be used for fertigation or in systems that reuse the liquid for diluting the dry matter fed into anaerobic digesters in biogas plants.

- Available in screen sizes of 0.015, 0.025 & 0.05mm.

- Self Cleaning Design.

- Throughput capacity of 10m³ / hour with fluids containing less than 10% dry material.

- SEPCOM Submersible Chopper Pumps and Agitators are also available.

SPECO Screw Compactor

SPECO Screw Compactor

Filquip offers a range of Speco screw compactors for industrial and municipal waste water treatment.

- The Shafted Washer Compactor can reduce screenings by up to 65% of their volume at a flow rate up to 6m³/hr.

- Available in Stainless Steel 304 and 316.

- Bagger option available.

WAM Shaftless Screw Conveyors

WAM Shaftless Screw Conveyors

Filquip supplies a large range of WAM trough shaftless screw conveyors.

- Trough screw diameters of 150, 200, 250, 300, 350, 400, 500 and 600mm.

- Numerous inlet and outlet options including spigot, round and square flanges and universal.

- Standard or custom built screw conveyors including options for multiple inlets and outlets, liners and wear bars, reversible operation and with inspection hatches as required.

- Throughputs of up to 100m³ / hr.