The experience of Filquip with supping bin activators for silos for many different products allows us to specify the correct type and size of bin activator to ensure good consistent mass flow of the product out of the storage silo.

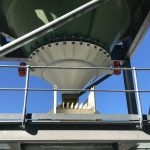

Gypsum Silo Bin Activators

Filquip has specified and supplied a new set of two (2) Gypsum Silo Bin Activators and Isolation Slide Gate Valves for a Plaster Board Manufacturing Company.

The following specifications were included for the Bin Activators

- Model BA.1.1.2500.

- Painted Mild Steel Construction.

- Supplied with VLC.400 Circular Slide Gates on the Outlet.

- Fitted with Twin MVE1600/3 Electrical Vibrators.

- SINT polymer gasket material.

These Gypsum Silo Bin Activators were supplied directly to site in a high cube container to ensure transport damage was not incurred for such large diameter units.

Lime Silo Bin Activators

Filquip has specified and supplied many Hydrated Lime, Quick Lime, Ag Lime and Lime Silo Bin Activators around Australia for industrial, agricultural and water treatment plant purposes.

This case study focuses on the Gibson Island Waste Water Treatment Plant in Brisbane and the Hydrated Lime Bin Activator on the Filquip supplied Silo System.

- Model BA.1.1.1800

- Painted Mild Steel Construction.

- Fitted with twin MVE1600/3 Electrical Vibrators

- SINT polymer gasket material.

This Bin Activator ensures a consistent mass flow of Hydrated Lime out of the storage silo into the Lime Slurry Dosing System below (Also designed, supplied and installed by Filquip).

Flour Silo Bin Activators

Filquip has specified and supplied a pair of two new Flour Silo Bin Activators to a Brisbane Flour Mill.

The following specifications were included for the Bin Activators

- Models BA.1.1.1800 and BA.1.1.2100

- Painted Mild Steel Construction.

- Fitted with twin MVE1600/3 IECEX DIP Rated Electrical Vibrators

- SINT-AL Food grade polymer gasket material.

This Bin Activator ensures a consistent mass flow of Flour out of the storage silo into the conveying systems below.

Fly Ash Silo Bin Activator

Filquip has specified and supplied a new Fly Ash Silo Bin Activator System with 4-20mA Positioner Butterfly Valve for a Pre-Mix building and construction materials company.

The following specifications were included for the Bin Activators

- Model BA.1.1.1250

- Painted Mild Steel Construction.

- Supplied with V2FS300 Butterfly Valve with 4-20mA Positioner Activator on the outlet to control flow.

- Fitted with MVE400/3 Electrical Vibrator.

- SINT polymer gasket material.

This Bin Activator ensures a consistent mass flow of Fly Ash out of the storage silo into the weight hopper setup in the plant.