Filquip has been providing Hopper and Silo Filling Systems for over 17 years for all types of powders and granular materials.

Dust Collectors

Dust Collectors

Filquip can provide a specialised industrial dust collection and air venting system specified to the correct sizing and requirements of any silo or process.

Pneumatic Conveying

Pneumatic Conveying

Filquip has specialist experience in Lean phase blow conveying, Dense phase conveying and Vacuum conveying systems all specified to meet customer requirements.

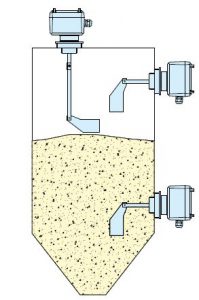

Silo Overfill Protection System

Silo Overfill Protection System

Filquip can supply a tailored silo overfill protection system to suit any system, to prevent dangerous over pressurisation and over filling, while eliminating dust emissions.

- Avoid damage to silo and accessories.

- Reduce the risk of air pollutions.

- Eliminate the risk of filling the incorrect silo.

- Start and stop the filter cleaner automatically.

- Systems can be tailored to suit applications including the need for Pressure monitoring, Over pressure or vacuum release valves, Fill control, Dust control and Operator destination selection panel.

Open Silo Overfill Protection System Page

RONCUZZI Bucket Elevators

RONCUZZI Bucket Elevators

Filquip is a supplier of RONCUZZI Bucket Elevators for vertically conveying bulk solids in powder, granular, pellet or chip forms.

- Available in Carbon Steel, Stainless Steel 304 and 316.

- Throughput rates up to 500m³ per hour.

- Discharge height up to 45m.

- Material operating temperatures up to 180°C.

Vigilex Explosion Panels

Vigilex Explosion Panels

Filquip is an Australian Distributor of Vigilex Explosion Protection Panels.

- Available many rectangular, square and round sizes.

- EPDM or Silicon Food Grade Gasket Options.

- Stainless Steel Construction.

TOREX ILT Level Indicators

Filquip is a supplier of Vibrating, Capacitance, RF and Rotating paddle level indicators.

- TOREX models ILT, ILTRO (Rotation control Multi-voltage), ILTD (24VDC), ILTCO (240VAC), ILTA (24VAC) ILV, ILS, IPE, IPM and KCS.

- Available with extension kits to suit any silo or hopper high or low level requirements (Standard 300, 600, 800, 1000mm).

- IP66 enclosure protection available.

- Multi-voltage output signals available.

Open ILS Continuous Level Measure Brochure

Open ILT Rotating Level Indicator Brochure

Open ILV Vibrating Level Indicator Brochure

WAM Pressure Relief Valves (PRV)

WAM Pressure Relief Valves (PRV)

Filquip can supply Spring-loaded (VCP) and Membrane (VHS) pressure relief valves to provide a safety net when abnormal pressure conditions develop in the silo, hopper or bin.

- Excess Pressure up to 900 mm H2O at a flow rate of 5,000m³/hour.

- Vacuum/Negative Pressure up to -50 mm H2O at a flow rate of 1,900m³/hour.

- Both VCP Spring-loaded and VHS Membrane Pressure Relief Valves are available in Stainless Steel of Polymer.

- Available with Duct to Ground emissions spigot.

Open VCP Spring Loaded Brochure

Open VHS-B Pressure Relief Valve

TOREX IP Pressure Sensor

Filquip is proud to supply the TOREX IPE Electronic Pressure Meter & IPM Mechanical Pressure Meter for monitoring of the pressure inside bins or silos during their filling and the purging of tankers.

- The pressure sensor membrane is self-cleaning and temperature resistant.

- The casing is aluminium alloy with IP55 protection rating.

- Available with 4-20 mA output signal configurations for IPE.

- 24VDC supply voltage

- IPX mounting spigot available for simple installation onto any silo

Open IP Pressure Sensor Brochure

EXTRAC Bulk Bag Unloader SBB

EXTRAC Bulk Bag Unloader SBB

The EXTRAC SBB Bulk Bag unloader provides an effective solution to unloading bulk bags of product in an efficient manner.

- Available in a half frame height where a crane or forklift is utilised to lift and hold the bag during unloading.

- Available in full frame height with telescopic rails for bag loading into the frame.

- Includes a vibrating pan plate and dust collection point to ensure efficient and clean bulk bag unloading.

- Optional bag massagers available for hard to move materials.

- Bulk Bag Unloaders are available in Carbon steel, Stainless steel 304 and Stainless steel 316.

Open SBB Bulk Bag Unloader Brochure

Silos

Silos

Filquip can supply Welded or Bolt together silo packages including all of the required Silo “Jewellery” to Australian Standards.

- Welded Silos available in custom built heights, diameters and capacities.

- Bolt together silo options from 35m³ to 125 m³. Allowing modular construction inside a building.

Open Bolt Together Silos Brochure

TOREX Pinch Valve VM

TOREX Pinch Valve VM

The TOREX pinch valve provides a valve seal which does not impede pneumatic conveying flow and is not as affected by the abrasive wear of pneumatic conveying.

- Available in sizes 0.5”, 0.75”, 1”, 1.25”, 1.5”, 2”, 2.5”, 3”, 4”, 5”, 6” and 8” diameter.

- Available in diameter sizes 13mm, 20mm, 25mm, 32mm, 40mm, 50mm, 65mm, 80mm, 100m, 125mm, 150mm, 200mm.

- System conveying pressure up to 3.5 bar.

- Low air consumption.

- Industrial or Food Grade Versions.

The pinch valve is operated by introducing compressed air into the threaded bore of the valve interior, the internal flexible sleeve is shaped to hermetically seal the passage.

Pinch Valve Control Panel

Pinch Valve Control Panel

The pinch valve control panel allows pinch valves to be used as diverter valves for pneumatic conveying lines.

The panel operates a set of solenoid air valves that open and close the respective pinch valves for each silo fill pipeline. An indicator on the panel displays which valve is open and closed.

Clear Pipes and Bends – Toughened Glass

Clear Pipes and Bends – Toughened Glass

The new Eurac Borosilicate Glass Clear Pipes and Bends and Tubing come in a wide range of diameters. The transparency of the borosilicate glass allows simple visual checks of the material flowing through the pipes or bends. With Electrostatic Protection from its Copper Conductive Strip and Food Grade properties (think Pyrex Glass) they are well suited to a large range of products.

- Borosilicate Glass has up to 10 times the abrasion resistance of Stainless Steel.

- Available in multiple tube and pipe diameters including 38, 40, 45, 50, 60, 63.5, 65, 70, 76, 80, 84, 88.9, 101.6, 104 and 114mm.

- Available in Straight Lengths, 45 Deg Bends or 90 Deg Bends.

- Industrially known as Spy Pipes, Sight Glass, See through pipes, Inspection pipes, Toughened glass bends and Inspection sections.

Open Borosilicate Sight Glass Viewing Pipes and Bends Brochure

Wear Elbows – Extrabend

Wear Elbows – Extrabend

Filquip provides a short radius wear bends with WAM patented geometry enabling diversion of the flow of the material at minimum wear.

Available in 2″, 3″ and 4″ Line sizes.

Wear Bends – Extracurve

Wear Bends – Extracurve

Filquip provides long radius wear bends made from patented WAM SINT engineering polymer cast around a helicoid spring core. The symmetric nature of the wear bends allows them to be mounted in reverse when they begin to show signs of wear from abrasive materials.

Available in 2″, 3″ and 4″ Line sizes.

Eurac Pipe Couplings

Eurac Pipe Couplings

Filquip is an Australian distributor and agent for Eurac couplings to join pipe or tube.

- Sizing from 38.1mm to 300mm in diameter.

- Suitable for all pneumatic and vacuum conveying operations.

- High working pressure.

- Available in Galvanised steel with Stainless Steel contact parts or in full 304 Stainless Steel.

- NBR seals supplied as standard, other options includes FDA approved food grade, Viton and Silicon seals.

EXTRAC Automatic Bag Splitters RSA

EXTRAC Automatic Bag Splitters RSA

The RSA Automatic bag splitter allows the splitting of bags loaded onto a conveyor belt by pressing and cutting.

- Product screening allows the bags to be completely emptied and the waste bag material removed from the product.

- Ideal for discharging dangerous products from bags safely.

Open Automatic Bag Break Station Brochure

EXTRAC Manual Bag Emptier RSM

EXTRAC Manual Bag Emptier RSM

The RSM Manual bag emptier allows the user-friendly splitting of bags in a dust controlled environment.

With easy connection to a screw conveyer, feeder or pneumatic conveying system for safe discharge of dangerous products.

Open Manual Bag Break Station Brochure

EXTRAC Waste Bag Compactors COM

EXTRAC Waste Bag Compactors COM

For disposing of large volumes of empty bags the COM Waste Bag Compactor is an efficient and economical solution. Available in Carbon steel and Stainless steel 304 with ATEX Zone 22 Certification.

Open Waste Bag Compactors Brochure