Bentonite Pneumatic Conveying System

Filquip has specified and supplied a lean phase bentonite pneumatic conveying system from two outdoor bulk storage silos into an indoors process hoppers 30m away at 8TPH:

The following Filquip equipment package was provided for the Bentonite pneumatic conveying system:

- 30kW Tri-Lobe Blower (950 m3/hr capacity, 70 kPag, with noise enclosure)

- Two blow through rotary valves (Model RVS20.20, Mild Steel, 1.1kW Motor)

- Full bore mechanical ball valves and Y pieces for diversion of clean air flow.

- Torex VAB.150 Flap Diverter Valve

Calcium Carbonate Lean Phase Conveying System

Filquip has designed and supplied a calcium carbonate lean phase pneumatic conveying system to move Omyacarb. The system transfers the Omyacarb Calcium Carbonate from a mill to a loadout silo a distance of 86m away at a rate of 25TPH.

The following Filquip equipment package was provided for the Bentonite pneumatic conveying system:

- Tri-lobe Positive Displacement Blower 75kW

- Acoustic Noise Enclosure for Blower

- One RVC35.20 Bent Rotor Rotary Valve 1.1kW

- Two FNW4J48 Air/Product Separation Dust Collectors

- One VAB.200 Flap Diverter Valve for Product Pipeline Diversio

Cement and Slag Pneumatic Conveying System

Filquip has designed, supplied and commissioned a Cement and Slag Lean Phase Pneumatic Conveying System to transport lime from outdoor Silos into the processing plant surge hopper above the mixer a distance of 45m away at a rate of 20TPH.

The following Filquip equipment package was provided for the Cement & Slag pneumatic conveying system:

- Tri-lobe Positive Displacement Blower 37kW

- Acoustic Noise Enclosure for Blower

- Two RVS20.20 Blow Through Rotary Valves 1.1kW

- Four Silotop Dust Collectors, Silo Pressure Relief Valves, Level Indicators and Slide Gates

- One VAR.150 Drum Diverter Valve for Product Pipeline Diversion

- Conveying Pipeline Wearbends

Cement Truck Unloader and Pneumatic Conveyor

Filquip has designed, supplied and commissioned a Cement Truck Unloading System that Pneumatically conveys the cement to internal plant silos at a distance of 50m away at a rate of 20TPH.

The following Filquip equipment package was provided for the Cement pneumatic conveying system:

- Tri-lobe Positive Displacement Blower 37kW

- Acoustic Noise Enclosure for Blower

- One SU.200 Screw Conveyor, 2000mm Long

- One RVS20.20 Blow Through Rotary Valve 1.1kW

- One FN1J06 Dust Collector with 1.1kw Fanset

Starch Pneumatic Conveying System

Filquip has designed, supplied, installed and commissioned a Starch Lean Phase Pneumatic Conveying System to transport starch from the bulk storage silo as required to the production hall day hopper a distance of 30m away at a rate of 6TPH.

The following Filquip equipment package was provided for the Bentonite pneumatic conveying system:

- Tri-lobe Positive Displacement Blower 11kW

- Starch Storage Silo 70m3 Capacity with aeration

- Silo overfill protection system (PRV, Dust Collector, Level Probe, Fill Valves)

- One RVS10.20 Blow Through Rotary Valves 1.1kW

Icing Sugar Mini Pneumatic Conveying System

Filquip has specified, supplied and commissioned a Icing Sugar Mini Pneumatic Conveying System to transport icing sugar dust from the Baghouse Dust Collectors into bulk bags. The Mini pneumatic transfer system conveys the dust a distance of 6m at a rate of 0.7TPH.

The following Filquip equipment package was provided for the icing Sugar Mini pneumatic conveying system:

- Compressed air control panel (PowerFil)

- Two Recofil Mini Pneumatic Conveying Systems

- One EasyFil Bulk Bag Filling System

- One Hoppertop Product/Dust Separator

Mobile Polyethylene Beads Transfer System

Filquip has designed, Fabricated, Supplied and Commissioned a Mobile Polyethylene Beads Transfer system to convey the PE beads from Bulk Bags or from Containers into site silos.

The following equipment package was supplied by Filquip all on a mobile skid frame:

- 30kW Positive Pressure Blower with Acoustic Enclosure.

- Half Height Bulk Bag Unloader with Truck Fitting Spout.

- Rotary Valve (Model RV35.20, SS304, 1.5kW Motor, Capacity 33m3/hr).

- Galvanised Skid and SS304 Piping Fork-Liftable (4800 x 1600mm).

- Local Control Panel (MCC and PLC) all prewired with Local Junction Box.

The use of this system has saved the customer the additional costs of the container delivery companies “Suck and Blow” Conveyor system mounted onto the truck and given them a range of product contained supplier options resulting in an annual cost saving of $200,000.

Brewery Pale Malt Grain Pneumatic Conveying System

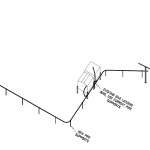

Filquip has designed, supplied, installed and commissioned a new lean phase Pneumatic conveying system to transfer bulk grain from new storage silos at the front of the Brewery a distance of 80m to the storage hoppers before the grain mill and mash in system. Filquip designed the system to run underneth the site access road through a trench and then over the roof of the plant.

The following Filquip equipment package was provided for this Brewery Pale Malt Grain Pneumatic Conveying System:

- 7.5Kw Side Channel Blower with Filtered air Intake.

- 20 Rotary Valve with IECEX Hazardous Area Motor.

- 80m of SS304 76.1mm Conveying Tubework, Bends, Clamps and Brackets.