Filquip is pleased to announce we are now stocking 304 stainless steel tube/pipe long radius bends available in 2”, 2.5”, 3” sizes (50.8mm, 63.5mm and 76.1mm Outside Diameters).

Supplied clean, deburred and wrapped with end caps ready for installation.

Open Filquip Long Radius Tube Bends SS304 Brochure

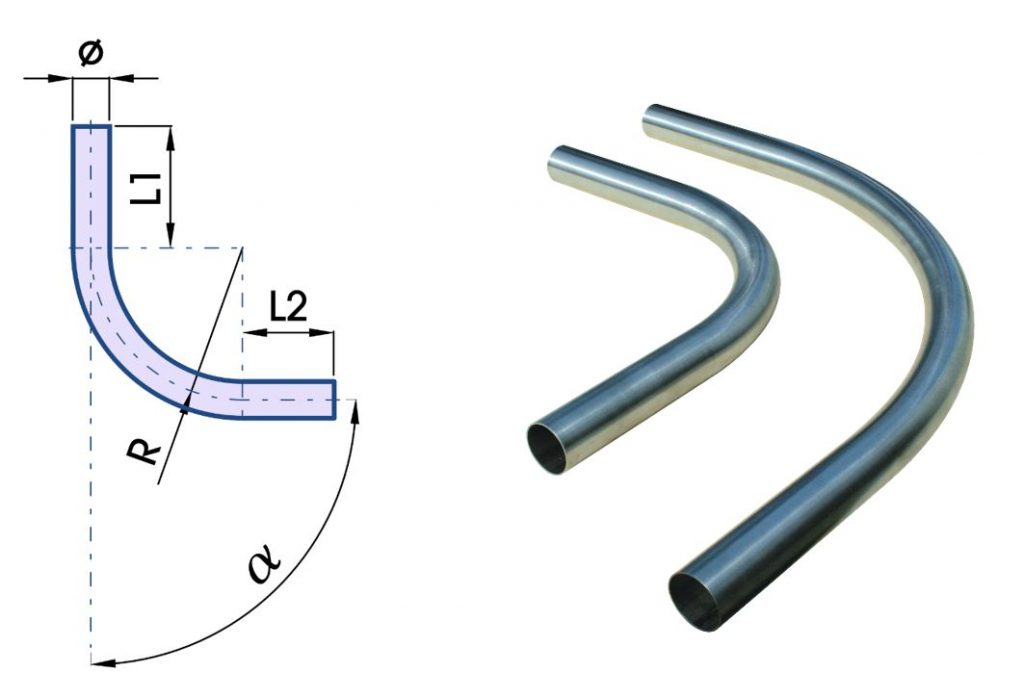

| Diameter | ⌀ | 2” | 2.5” | 3” |

| 50.8mm | 63.5mm | 76.1mm | ||

| Wall thickness | 1.6mm | 1.6mm | 2.0mm | |

| Angle | α | 90° | ||

| Radius | R | 500mm | ||

| Tail Length | L1 | 200mm | ||

| L2 | 200mm | |||

| Pipe end | Internal Chamfer | |||

| Size | Part No. |

| Stainless Steel Bend 50.8mm | BC5W05081505902 |

| Stainless Steel Bend 63.5mm | BC5W063515050902 |

| Stainless Steel Bend 76.1mm | BC5W076120050902 |

| Available ex stock from Filquip in Brisbane | |