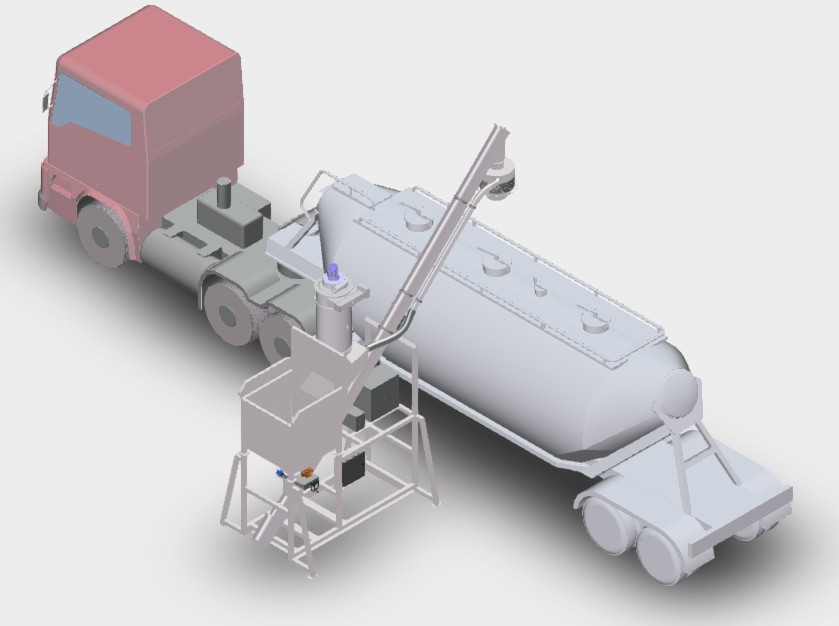

Filquip with our partners design, fabricate and supply a range of Mobile Bulk Bag Unloader systems with bag splitters and integrated screw conveyor to decant to products.

The following equipment packages have been designed, supplied and commissioned:

- Hard wearing bag splitting knife.

- 1m3 Storage Hopper with Electric Vibrator for product flow.

- Modular Screw Conveyor (De-mountable for transport or storage).

- Local control panel, wired ready for use to the motors.

- Optional Extra: Winch operated bellow with inner and outer chute for dust control.

- Optional Extra: Integrated Dust Extractor with Fanset for dust control.

- Optional Extra: Lump breaker for the hopper transition into the screw conveyor.