Filquip has specified, supplied and installed a MAP Continuous Mixer for Bentonite and PAC powders. The project commenced with R&D works using a MAP lab mixer to ascertain the required mixing residence times and to deliver a proof of quality control in mixing of the Bentonite and PAC (Powder Activated Carbon) powders.

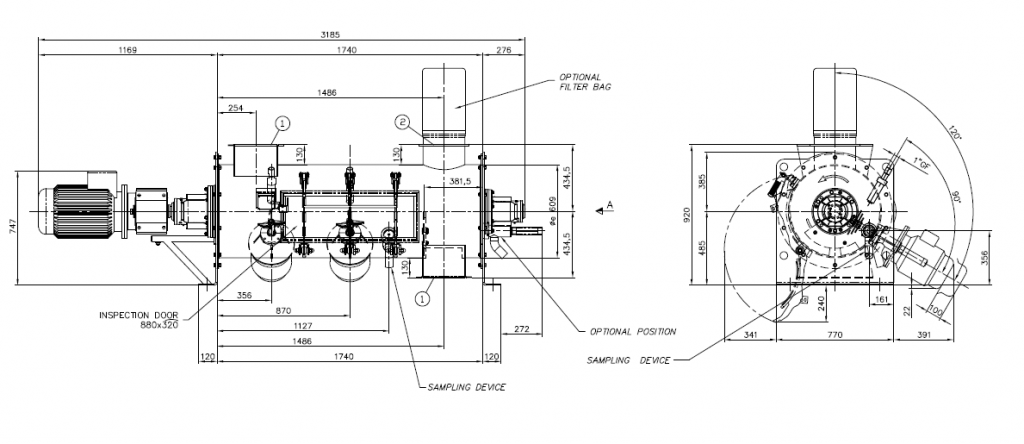

- Model: WAHV.0500.PO

- 5m3/hr Mixing Capacity at 50% fill factor, 60 second mixing residence time with 1:100,000 dispersion for maximum mixture homogeneity.

- 5kw Motor and Gearbox Combination

- Pneumatic Sampling Device Included

The mixers Filquip supplies by MAP are made to measure from standardised modular components, carefully selected to the relevant mixing process requirements.

WAH Continuous Horizontal Single Shaft Mixers use a single mixing shaft inside a cylindrical mixing drum vessel with an inlet, and an outlet at the opposite end. Ploughshare or inclined blade-type shovel tools rotate as mixing tools in a special arrangement on the mixer shaft in the drum. The result is a turbulence in the mix that constantly involves all the product particles in the mixing process. The formation of dead spots or slow-movement zones in the mixing drum is prevented ensuring precise mixing.

The quality of the mixture is achieved before the product reaches the mixer outlet. Continuous WAH Series Mixers are suitable for dry bulk solids (powders, granules, fibres), dry bulk solids + liquids (moistening + granulating), sludge and low-viscosity pastes.

View the Filquip MAP Mixers Range