Dense Phase Conveying vs Lean Phase Conveying

Usually when we think of dense phase pneumatic conveying, two basic measurement parameters appear in our mind: Pressure and Velocity.

The combination of these two variables generates the movement of the material, both powders or granules.

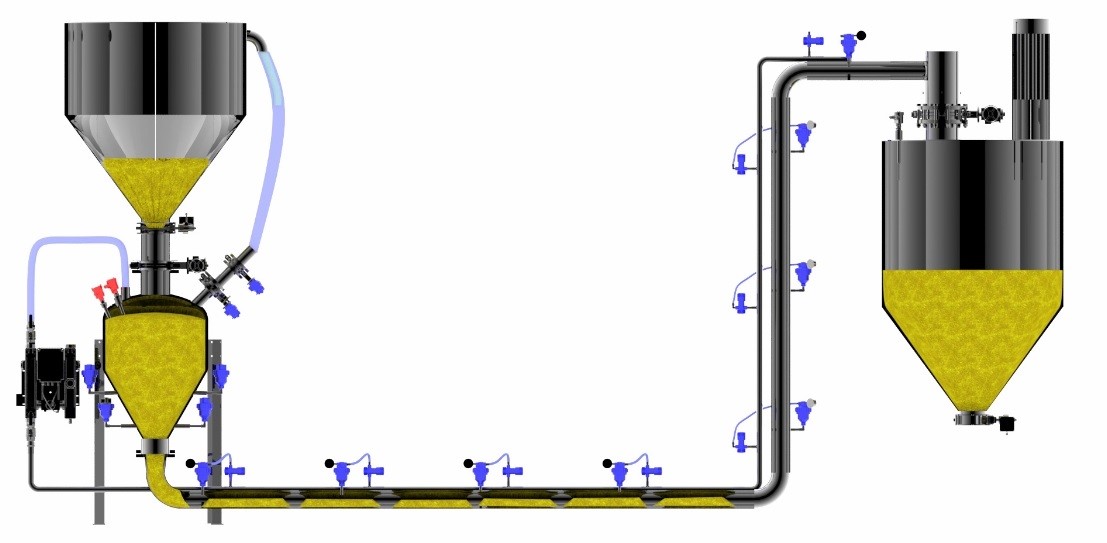

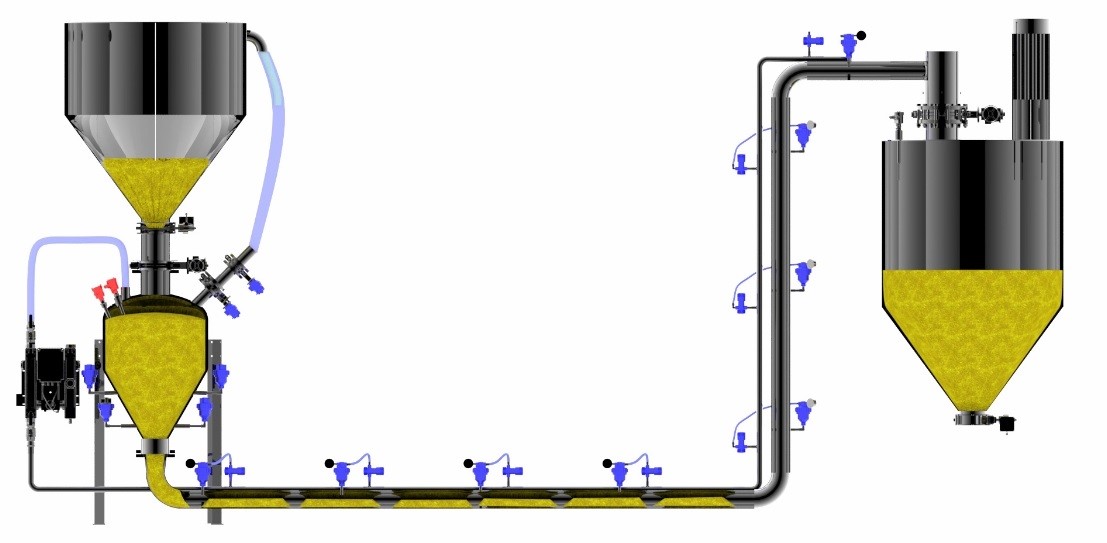

In dilute lean phase conveying, the combination of low pressure and high speed makes the particles move while suspended in the air inside the pipeline. Whilst, in dense phase conveying the particles form plugs which are then pushed through the pipeline by compressed air. Precisely for this reason dense phase conveying method is the best choice in the case of fragile, mixed or abrasive products.

The Dense Phase Pressure Vessels are the main proponents of dense phase technology. They make it possible to move bulk materials from one point to another within a closed pipe, whether horizontal or vertical, by means of a gas (usually compressed air or nitrogen).

Let’s take into account the transport pressure.

Inside a dense phase pneumatic conveyor, the high pressure gently pushes the material inside the pipeline, sometimes with the help of special systems for the introduction of air. Pneumatic conveying always requires a pressure difference between the beginning and the end of the line. This difference depends not only on the length and layout of the line, but also on the concentration of the material within the pipeline. Likewise, the pressure is influenced by the physical characteristics of the product and the flow rate.

The low speed is what most distinguishes dense phase technology from the dilute lean phase one.

Compressed air at the beginning of the line expands as it approaches the end of the line, so that the speed also increases. Within a dense phase transport system, the speed can vary at the point of arrival, but rarely exceeds 10 m/s.

The right combination of high pressure and low speed creates the homogeneous flow of product plugs within the conveyor line.

Dense Phase pneumatic conveying is extremely flexible in terms of the routing and the length of the pipeline.

The main application fields of pneumatic conveyors are feeding operations of mixers, reactors, packaging machines, and every similar application that requires to handle powders, granules, flakes, and dry bulk.

Pneumatic conveyors are used primarily for granules and powders. Some commonly conveyed products include sugar, flour, coffee, plastic granules, chemicals products, cement, silica sand, feldspar, fly ash, glass cullet, alumina, glass batch mix, and carbon black.

The correct design of a dense phase conveying system has the right balance between pressure and speed in order to prevent the breakage of the material, the wear of the pipeline or the formation of clogging in the case of delicate, abrasive and cohesive materials of those that react to temperature changes.